Jun 03, 2002· the cause is typically failure to analize all stresses and the fatigue strength for those stresses. The fatigue strength is influenced by the juncture and welding details. The writer experienced pulley failures due to circumferential cracks that, in each case, began at an internal disc, welded in the pulley to insure roundness.

causes conveyor belt failure

The location of the conveyor belt or the number of items that have been stacked onto a conveyor belt have been to cause catastrophic injuries. Improperly Assembled Belts: Failure to adequately follow instructions when constructing conveyor belts can create a significant risk of workers being injured. Conveyor belts must be assembled according to the applicable instructions.

Meanwhile the conveyor belt doesn't stop. Another bumper MCG crowd worth of kids is falling over the edge every year while academics and politicians argue. The 'balanced literacy' advocates cry that their method is superior, and yet the 19% failure rate persists.

The tension in a conveyor belt decreases as the belt travels around the drive pulley, causing the belt to contract. In order to prevent slip, the lagging must deform circumferentially to match the belt contraction. The belt traction force causes this lagging deformation but, if beyond the limit friction, will allow slip.

Nov 20, 2017· Blog: Top 3 problems that can bring your conveyor to a halt. The challenge is that conveyors typically operate in extremely demanding conditions: dirty environments, intense heat, high moisture and very low temperatures. If poorly maintained, a conveyor may experience rapid belt wear and component failure, with consequent stoppages and downtime.

Premature conveyor roller failure can be caused by rollers that are incorrectly specified or when they are subject to poor operating conditions. Premature roller failure can also occur when the roller is clogged, jammed or buried under fugitive material that has fallen from the carry side of the conveyor belt (see MATERIAL CARRYBACK and SPILLAGE).

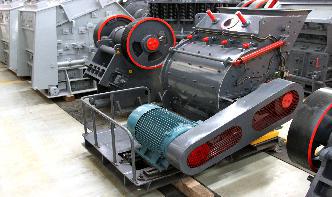

mechanical drive for belt conveyor. So friction is the driving force. In order to raise transportation efficiency of belt conveyor, driving force of drum must be increased. Energy saving efficiency, friction, fire safety, maintenance and inspection are the other key factors of belt conveyor design.

Jun 22, 2018· 3 – Electrical Supply. Phase voltage unbalance in a threephase supply can cause electric motor failure due to an excess temperature rise. A 3% voltage unbalance causes an 18% temperature rise in the motor and a current increase of six to ten times the voltage unbalance. Phase voltage imbalance should be less than 1% for proper motor operation.

failure. 4. Failed belt cleaners with excessive material between the belt carcass and the pulley lagging. 5. Excessive water between the belt carcass and the pulley lagging. 6. Worn pulley lagging. 7. Collapsed pulley bearing skewing the belt into support structure. 8. Jammed belting due belt wander. 9. Jammed belting due to blocked transfer chute. 10.

power plant and other projects. Belt conveyor will often occur some typical problems in the course,this paper Based on research common typical failureof belt conveyor during use,analysis the cause of failure,proposed some effective methods to solve the problem. 2. Typical faults of conveyor belt Conveyor belt deviation

The number one cause of a power transmission belt failure is improper tensioning. In order to ensure a long and efficient belt operation, you must properly learn how to tension a Vbelt regularly. If they are too loose, there is slippage, rapid belt or sheave wear and, ultimately, loss of both energy and productivity.

Some common causes of seat belt failure: Seat belt latch failure. A seat belt buckle can unlatch inadvertently, which can be caused by inertial unlatching, false latching, and inadvertent unlatching. Spooling. Spooling occurs when too much of the seat belt webbing is let out, which causes movement in the occupant. Retractor failure. Retractor failure occurs when the lock or tightening of the seat belt .

Cause: Failure of bearings or pivot area will cause excessive noise. Solution: Replace the tensioner. Also read our guidelines to correctly diagnose accessory belt drive noise. 6. Tensioner arm misalignment. Appearance: Abnormal belt tracking on tensioner pulley. Shiny, .

Quality conveyor belts suited to the materials they carry provide longer lifetimes and less downtime for repairs "Apart from an insufficient resistance to heat, the most common cause of failure in heatresistant belts is when a belt loaded with hot material is allowed to become static. This allows the heat to penetrate through to the carcass."

a conveyor belt, such a belt presents danger in terms of safety as it can get torn up and cause injuries to people in its vicinity. If the conveyor belt is not centered with respect to the structure,

The higher initial cost of the belt conveyor is offset by the higher, on going expense of trucks, such as the cost of truck mechanical maintenance and tires, the driver and the distance related cost of fuel. Needless to say, belt conveyors serve a vital link in the movement of numerous types of materials.