For example, it was shown that milling in a mixer ball mill (MBM) for 10 min with two milling balls in a 10 ml beaker raised the temperature from 25 to 30 °C, and Colacino and coworkers measured a temperature increase of approximately 14 K after 30 min milling in an MM200 mixer mill [6, 11].

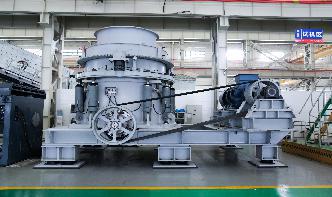

ball mill of metal oxide

How to decrease particle size of alumina powder with ball milling? I have 63 micron alumina(Al2O3) powder and I want to decrease its particle size down to 1520 micron with ball milling. I have a ...

Ball mill. The inner surface of the cylindrical shell is usually lined with an abrasionresistant material such as manganese steel or rubber. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.

Ecutec produces an array of grinding technologies including ball mills, pin mills, jet mills and roller mills. Each type of mill has its own set of parameters and considerations, and Ecutec engineers have the expertise to recommend the right mill for each application. read more; Coating

Physical methods, which often involve vapor deposition, or ball milling process require subdivision of bulk precursors to nanoparticles. Chemical procedures start from reduction of metal ions to metal atoms, followed by controlled aggregation and separation of atoms from the bulk.

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

Aug 22, 2016· Metal oxides are formed as a consequence of coordination tendency of metal ions so that oxide ions form coordination sphere around metal ions and give rise to close packed structure. The different physical, magnetic, optical and chemical properties of metal oxides are of great interest to chemists because these are extremely sensitive to change in composition and structure.

Characterization of Metallic and Metal Oxide Nanoparticles Produced by ElectrothermalChemical Synthesis Kurt A. Schroder, Dennis E. Wilson, Kyoungjin Kim, and Henry E. Elliott Jr. Nanotechnologies Inc. 1908 Kramer Lane, Building B, Austin,TX78758, ABSTRACT ElectrothermalChemical Synthesis (ETCS) is a relatively new process for the synthesis

Apr 11, 1989· The coated materials selected among different metal oxides were: aluminum oxide, titanium dioxide, zirconium dioxide, chromium oxide, nickel oxide and silicon dioxide. The final product of this procedure is a zinc metal flake coated with a thin layer of a metal oxide, which may be either leafing or nonleafing, and in dry or paste form.

The support material is usually an alumina or other metal oxide and may play a key role in the catalytic procedure either directly or by affecting the active material. Catalysts can come in a precursor form, which must be activated before usage.

metal oxide into a complete metal alloy. Previous experiments had shown that multiple transition metals could be converted from an oxide to the metallic form, indicating a possible replacement for the standard metal refining process of heating the metal oxide in a blast furnace to ℃.

The preparation of titanium carbide/aluminum oxide (TiC/Al 2 O 3) nanocomposite powders from a mixture of titanium, carbon, and Al 2 O 3 powders via a high‐energy ball milling process and subsequent heat treatment was investigated. The microstructure development of the powder mixtures was monitored by X‐ray diffraction and transmission electron microscopy.

The requirement of oxygen for combustion naturally led to production setups under oxidizing atmospheres. This circumstance, of course, impedes the synthesis of reduced materials, such as metal nanoparticles, as these would immediately react with oxygen, water or CO2 in the flame atmosphere, forming metal oxides.

process. It is noteworthy that the multistep process based on the Mn(II)/Mn(III) oxide system can be carried out at 700 °C or 750 °C. The twostep process has been achieved at 1,300 °C/900 °C by using yttriumbased rare earth manganites. It seems possible to render this hightemperature process as an isothermal process.

Jan 10, 2010· Aluminum Powder is an ingredient in thermite and when ground fine enough becomes a flash powder that could demolish a building in use it to create a bright light for a picture, wood workers use it to fill joints, and aluminum powder was even what the tin man used as makeup.. Supplies. The supplies for this one are easy, just aluminum and something to grind it in.

Find highquality crystal substrates, sputtering targets, lithium battery materials, ITO and FTO substrates, milling equipment and accessories, and analytical services for advanced materials research and production at MSE Supplies.

In materials science, "green" synthesis has gained extensive attention as a reliable, sustainable, and ecofriendly protocol for synthesizing a wide range of materials/nanomaterials including metal/metal oxides nanomaterials, hybrid materials, and bioinspired materials. As such, green synthesis is regarded as an important tool to reduce the destructive effects associated with the ...

Ball mills are built in Overflow and Diaphragm types. In the Overflow mill the material is discharged by new feed moving into the mill and displacing a mixture of solids and water being ground within the mill. The diaphragm arrangement in a ball mill is a positive means of pumping pulp or .

Mar 19, 2015· Facile synthesis of iron oxides/reduced graphene oxide composites: application for electromagnetic wave absorption at high temperature ... In the process of mechanical grinding and ball milling ...

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. The PM 100 is a convenient benchtop model with 1 grinding station. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the .

The effects of metal oxide nanopowder (Fe2O3, Cr2O3, ZnO and MoO3) additions by dry ball milling on the hydrogen desorption behaviours of LiAlH4 have been investigated. Among them, adding Fe2O3 leads to the most pronounced improvement on the onset dehydrogenation temperature and .

University of South Florida Scholar Commons Graduate Theses and Dissertations Graduate School Effects of Zn Doping and High Energy Ball Milling

Usually the metal acetate and the organic proligand are mixed and ground up with a ball mill. Cu 3 (BTC) 2 can be quickly synthesised in this way in quantitative yield. In the case of Cu 3 (BTC) 2 the morphology of the solvent free synthesised product was the same as the industrially made Basolite C300. It is thought that localised melting of the components due to the high collision energy in the ball mill may assist the .

»ball mill for cereal grinding; Mill (grinding) After the grinding the state of the solid is changed: the grain size, the grain size ... Ball mill; Rod mill; Autogenous mill; SAG mill; Pebble mill... More details » Get Price