ANALYSIS OF EFFICIENCY OF GRINDING IN BALL AND ROD MILLS DEPENDABLY ON CONTENTS OF FINE PARTICLES IN FEED** 1. Introduction About efficiency of mill work the parameters of work decide, like rotary speed, load, grinding medium contents, sort .

ball mill efficiency factor

factor affecting the efficiency of ball mill grindin Factors Affecting Ball Mill Grinding Efficiency. 201947 · The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical ...

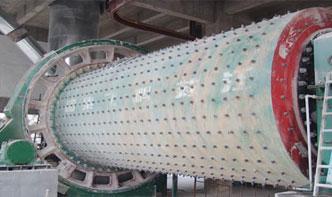

Grinding Mills Crusher Feldspar April 18,2019. A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them.

Nov 23, 2012· > Ore Process > recirculating load in ball milling formula; Print. recirculating load in ball milling formula. Posted at:November 23, 2012[ 2604 Ratings] ball mill circulating load calculation. ball mill circulating load ball mill critical speed calculation ball mill . Calculation Screen Efficiency Factor .

ball mill efficiency consultant ic4u. ball mill efficiency factor. making your own porcelain ball mill jars With the PVC ones I would wonder if you would lose milling efficiency by having the smooth . Get Price And Support Online; The energy efficiency of ball milling in comminution .

Moisture Removing Increasing Efficiency in "Ball Mill" Kawaljit Singh Randhawa Assistant Professor Department of Mechanical Engineering CSPIT Changa Abstract—Ball mill is used to crush partials into powder form. Calcined bauxite can be manufactured with the help of ball mill by grinding the raw bauxite and converting it to

Ball Mill Loading Dry Milling. Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product.

load factor of a ball mill wet ball mill_Ball Mill Design/Power CalculationBall Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index

There are many factors influencing the grinding efficiency of ball making machine. As for one ball mill grinder, when processing one mineral, the influencing factors of grinding efficiency include property of grinding media, matching of grinding media, filling ratio of grinding media, ratio of grinding balls to materials, grinding density and feeding granularity.

The factors that effect ball mill energy efficiency are reviewed, and attention is focused on the mechanisms of grinding. The trajectory of the outer row of balls with different lifting face ...

Jan 13, 1987· An electric motor operated rotary drum type grinding mill is operated at optimal efficiency by detecting and analyzing the motor current. The power signals are converted by signal processing equipment ... Methods of operating ball grinding mills . United States Patent ... one other factor affects tunnelling (48), namely: raw material ...

Factors Affecting Ball Mill Grinding Efficiency. The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this ...

the factors affecting the efficiency of mill grinding. factors affecting the ball mill grinding Factors Affecting the Efficiency of Ball Mill College Essays, 2 Apr 2012, Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as .

Jun 29, 2013· To improve working efficiency of ball mill, Machinery makes some technical improvement on its structure. The rotation speed of ball mill is the main factor directly influencing the working efficiency of ball mill, for this reason, improving its rotation speed will directly improving its working efficiency.

Factors Affecting Ball Mill Grinding Efficiency. The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this ...

Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics, and ball mill also can be used for the dry and wet grinding for all kinds of ores and other grindable materials. 1, The impact of media ...

factor affecting the efficiency of ball mill grindin. factors affecting grinding efficiency of ball mill . Factors Affecting the Efficiency of Ball MillCollege Essays Ball mill is the key equipment for grinding after the crush process, and it is widely used in the. Get Price

Rod mills are less common than ball mills for grinding minerals. The rods used in the mill, usually a highcarbon steel, can vary in both the length and the diameter. However, the smaller the rods, the larger is the total surface area and hence, the greater the grinding efficiency. Autogenous mill

The main factor in the ball mill grinding equipments . Nov 17, 2014The main factor in the ball mill grinding equipments defect? resulting in poor coal fineness or reduce output; on the other hand will result in the formation of failure of the ball, affect output or leaving the ball because the ball .

Correlation between process parameters and milling efficiency DiVA. well as the kinetic energy of the milling ball affected the size reduction; more ... scaling factor based on the weight of the WC and milling balls. ..... glycol, PEG, and grinding liquid, a mixture of ethanol and water, in a cylindrical ball mill and...

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that .