Cement, better known in industry as Portland cement, is a major ingredient in concrete. Mixing Portland cement with different kinds of aggregate crushed limestone, crushed sandstone, sand and gravel, etc. (see the section on 'aggregate') and water creates concrete.

iron ball used in cement industry project report

Ball Mill Manufacturers, Ball Mill Suppliers Global Sources Wide range of Ball Mill manufacturers from Global Sources ☆ High quality Ball Mill supplied by Ball Mill suppliers. ...Ball mill, used industry or cement plant for store and ore grinding. MOQ: 100 Sets .... Sphere Engineers Private Ltd. India.

Ball Millis widely applied in cement industry ... speed of a ball mill. the ball will rotate with ... working principle of cement ball mill Ball mill Wikipedia A ball mill is a type of grinder used .

efficiency of cement ball mill for engineers report. In the cement/concrete industry improvement of energy efficiency and, tube mills, ball mills, and conventional or highefficiency separators (IEA, 2009), Global demand for cement is forecast to grow by 47% annually to 28 billion metric.

Aug 30, 2012· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

Aug 30, 2012· Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

and alumina. Finished cement is produced by finely grinding together around 95% cement clinker with 5% gypsum (or anhydrite) which helps to retard the setting time of the cement. The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 80–90% of raw material for the kiln feed is limestone.

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

Jun 19, 2012· Working capital management project report mba Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

Cement is a finely ground powder which, when mixed with water, forms a hardening paste of calcium silicate hydrates and calcium aluminate hydrates. Cement is used in mortar (to bind together bricks or stones) and concrete (bulk rocklike building material made from cement, aggregate, sand, and water).

Iron, Fe 2 O 3: from from clay, iron ore, scrap iron and fly ash Gypsum, CaSO 4 .2H 2 0: found together with limestone The materials, without the gypsum, are proportioned to produce a mixture with the desired chemical composition and then ground and blended by one of two processes .

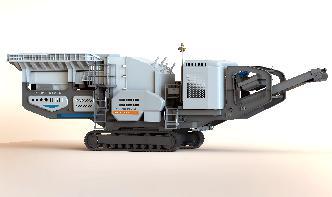

CHAENGMining Equipment Suppliers. Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

The focus of this Guide is on energy used in the production of cement clinker; unlike finished cement, all plants produce clinker. Most of the energy information in this report was provided by the Cement Association of Canada (formerly known as the Portland Cement Association of Canada).

Ball mill is the main equipment of ore dressing process, and it is widely used in mining, metallurgy, building materials, refractory, cement, chemical and thermal power the rapid development of all walks of life, the ball mill is used more and more widely.

Cement manufacturing is the third largest energy consuming and CO 2 emitting sector, with an estimated Gt of CO 2 emissions from thermal energy consumption and production processes in 2006. 1 If Best Available Technologies can be adopted in all cement plants, global energy intensity can be reduced by GJ/tcement, from its current ...