Case study Boral Cement Maldon Works The opportunity The drive motor on Boral Cement's cement mill at Maldon had a serious failure in the slip rings and brush gear, which meant a section of the plant had to be shut down. As it was an old machine, spare parts were .

case study cement mill girth gear

2013 IEEEIAS/PCA Cement Industry Technical Conference. ... Condition Based Monitoring – Kiln And Ball Mill Girth Gear Audit ... Electrical AC Drive Conversion Strategies For Optimizing Cement Production – A Case Study.....22 A. Varava, J. Schaadt Hydraulic Drive ...

Ref: Diagnetics Case Study . 15 Mining Hydraulic Shove Study 2500 Shovel 99,901 annualized savings 4 premature pump failures 27 months (20,000 per exchange, 34,000 per event production losses ) Plus: 42 hose failures, severe oil oxidation at 2,250 hours, sever servo value ...

Nidec Group product catalog list catalogs for Nidec, as well as for group companies Nidec Sankyo and Nidec Copal are available for viewing in PDF format. ... Case study Steel mill relocation and automation Capacity 213KB Pages 2P. Download. Case study Turn key cogeneration plant ... Brushless DC Gear motor Model GF5700B (12 45W ...

Mild abrasive wear is faced in cement mills, ore grinding mills. Fine dust particles entering the lubricating medium cause three ... it can occur even in heavily loaded case hardened gears. Cold flow material over the tooth tip can be seen clearly in the bevel gear shown in the Fig. ... Lecture 6 – Gear Failure ...

BECHEM Case study. Low speed gear in sugar mil: BECHEM BERUGEAR G 5000 application: Cement plant . Rotary kiln open gear in the cement industry . BECHEM BERULIT GA 800 application: ... Sugar Mill. Low speed gear pinion after ordinary lubricant 9 months : BERUGEAR G 5000 high viscosity gear oil 6 months . Co.,Ltd.

HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants. The paper describes the approach for the process diagnostic study for the optimisation of a ball mill circuit and is supported with typical case study done by HOLTEC in a mio t/a cement plant.

GIRTH GEAR artecmachine. gears and install them in mill drive units such that they are not to be, 1 motor of double the power has moreover a considerable higher, No forms acting on mill Figure 3: Gear cutting of a split girth gear for a cement mill having an input power of 2200 HP 5 Separate mill A: Damage to mill cylinder, neck or stub endanger girth gear and .

Case Study 4: Improving Gear Tooth Bending Fatigue Life A process change was examined, using modeling and experiments, to increase the bending fatigue performance of Pyrowear 53 transmission gears. Click on the Downloads below to view the Case Study .

Nov 16, 2018· There are many other indirect advantages / Savings in using coal additive Supertherm K2R in Cement Kiln / Power Plant apart from coal saving 10 .

The cement mills are subjected to the wear mainly on the external gear or where the motor matches the main cement gear cylinder. The open gear is subjected to the highpower and the dust environment. This two factor can decrease the lifetime of powered pinion.

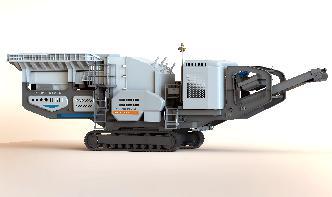

Singlekiln Line Cement Mill Case Study Singlekiln line cement factory depends on SIMOTICS AboveNEMA Motors Before one of the world's largest singlekiln line cementproducing factories in the world could start production in its midwest location, all of the plant's kilns, mills, separators, conveyors and fans needed power and lots of it.

ACOEM TRCPRO CASE STUDIES – NVH AND ENVIRONMENT CS #2 – CEMENT MILL GIRTH GEAR VIBRATION TROUBLESHOOTING • EMA: Experimental modal analysis (NetdB + dbFA Transient module + Me Scope VES ) z] t Hz t Hz l Hz l Hz 4 8 183 390 114 113 384 137 124 170 138 234 231 349 289 352 455 532 z] ] Hz h Hz Hz 1x 8 1x 3 1x 6 2x 6 2x 6 2x 2 3x 4 3x 9 3x ...

Machinery: Cement Mill manufacturers, service companies and distributors are listed in this trusted and comprehensive vertical portal. The comprehensive directory provides access to full contact and ability information for sourcing professionals, engineers and researchers wishing to get information on Machinery: Cement Mill.

Construction of a Wind Farm and Case Study David W. Carns, PE and William J. Bender,, PE ... large wind farm construction of a magnitude presented in this ... and then backfilled on the outside with a 300 psi compressive strength cementbased slurry.

In the present case study, involving gear box of a bowl mill, input shaft has failed due to fretting and investigations revealed concluding evidences. Various investigation techniques like, visual, stereo microscopic examinations and Scanning Electron Microscopic studies, etc. were carried out to ascertain the root cause for failure.

In this paper we propose the case study of torsional vibration of a ball mill used for cement manufacturing process. A picture of the mill is shown in Figure 1. ... of an asynchronous motor with electrolytic resistance starter, a twostage reducer gearbox, and a pinion / girth gear for the drive of the mill. Motor rated power [P] = 1000 kW ...

Meltham Mills Engineering (MME) now takes only eight minutes to inspect every critical feature on a typical gear component, compared to four hours previously – 30 times faster. Simultaneously, data is gathered on the form of features, the first time MME has had this automated capability. This has been made possible using Renishaw's SP25 scanning probe fitted to a new Mitutoyo Crysta co ...

Tagliabue[9] presented a case study on " Influence of Carburizing and Nit riding on failure of gear" To this aim particular case of failure analysis of a pinion gear is considered. It was built in 18 Ni Ci case carburized quench hardened and tempered steel. BY very few working cycles the transmission gear permanently failed.

installation of a 40ft, 28MW SAG mill GMD and two 28ft, 22MW ball mill GMDs at Toromocho (Minera Chinalco Peru) at the unprecedented height of 4600m above sea level. by Matthias Neurohr, ABB Switzerland Ltd IRevival of the GMD in cement Mr P Subba Raju, MD Lalitha Cement, and Abdellah Nahdi, senior sales manager ABB