Antimony is a silverywhite metal that is found in the earth's crust. Antimony ores are mined and then mixed with other metals to form antimony alloys or combined with oxygen to form antimony oxide. Little antimony is currently mined in the United States. It is brought into this country from other countries for processing. However, there are companies in the United States that produce antimony ...

technology for antimony oxide ores

Rather, the antimony removal costs are presented in the form of percent of sale values of the mined product(s). For example, if the total annual antimony removal technology cost is 10,000 and the total value of the mined and recovered products is 1,000,000 per year, then the cost would be one percent of product value. Calculating antimony ...

Antimony ore proportion is heavy than matrix,normally gravity separation is more . After grinding and flotation the tailings from the gravity separation,use one. Contact US Current processing technology for antimony bearing ores a review . Antimony Wikipedia. Production process. The extraction of antimony from ores depends on the quality and ...

Common gravity separation technology includes heavy medium separation, jig separation, and shaking table separation. The technology dealing with manganese oxide ores usually crushing ores into 06mm to 010mm, and then classifying. The coarse minerals are sent to jig separation, and the fine minerals are sent to shaking table separation. 3.

Audio Books Poetry Community Audio Computers Technology Music, Arts Culture News Public Affairs NonEnglish Audio Radio Programs. Librivox Free Audiobook. ... Full text of "The antimonymining industry and the distribution of antimony ore in New South Wales"

Jan 12, 2014· ANTIMONY ORE BENEFICIATION PROCESS PATHS Oxide ores Mixed ~50% Sulphide ores (marketed as lump sulphide, clean sulphide Chinese concentrate) ~50% 1 25 45% % 25% 45% 60% > 59% 2 Crush, mill, float 3 Carbon, soda Pressure cynidation in pipe reactor Leach Electrolysis Reduction in reverbatory or short rotary Liquation in reverbatory or ...

Grant, in Encyclopedia of Materials: Science and Technology, 2001. Antimony–Arsenic–Tin Softening. Antimony, arsenic, and tin (which form hard lead alloys) are removed by oxidation with air or oxygen. The process uses a small reverberatory furnace at about 650 °C operating in batch or continuous mode, or a batch pan.

Antimony Ore Beneficiation Washing Plant. There are three kinds of antimony ores according to the beneficiation technology. And they are single antimony sulfide, stibnite and antimony sulfideoxide mixture. There is some other antimony ore mixed in stibnite ore together with some lead, tungsten, mercury minerals. The main separation way for ...

Antimony ores are mined and then either changed to antimony metal or combined with oxygen to form antimony oxide. (1) Antimony trioxide is a white powder that is very slightly soluble in water. (1) Antimony metal is a very brittle, moderately hard metal. (1) The chemical symbol for antimony is Sb, and it has an atomic weight of g/mol. (1)

Commercial production and uses. Highgrade or enriched stibnite reacts directly with scrap iron in the molten state, liberating antimony metal. The metal can also be obtained by conversion of stibnite to the oxide, followed by reduction with sulfide solutions are effective leaching agents for the concentration of stibnite from ores.

how to process antimony ore saneringchemiepacknl. current processing technology for antimonybearing ores a, canada the type of ore processed here is mostly stibnite but also contains a small proportion of native antimony the ore process dissolved antimonyantimony miningcommoditymineinfomine, antimony mining jobs, antimony mines single process arsenic and antimony removal antimony .

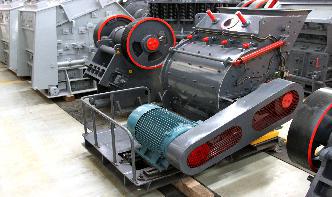

Antimony Mining Equipment Supplier,Antimony Ore . Antimony Ore Beneficiation Process Equipment. Antimony ore beneficiation technology equipment first with a forehand and backhand general election antimony ore output section or gangue, tailings use or discard some heavy media; single antimony ore generally recovered by flotation; elimination of mixed ore is first mixed output concentrate, and ...

Antimony has been produced from ores in over 15 countries. As shown in Table 2 (Carlin, 2012), world reserves of antimony are ... Anderson / Chemie der Erde 72 (2012) S4, 3–8 5 Table 3 Plant capacities of historic leading producers of refined antimony.

Rather, the antimony removal costs are presented in the form of percent of sale values of the mined product(s). For example, if the total annual antimony removal technology cost is 10,000 and the total value of the mined and recovered products is 1,000,000 per year, then the cost would be one percent of product value. Calculating antimony ...

The difficulty of roasting arsenical and antimonial ores may be avoided by taking ore, 1 ; red lead, 1,000 grains; sodium carbonate, 500 grains; potassium ferrocyanide, 550 grains, with a cover of salt or borax. The button is scorified, together with the matte formed, before cupellation. E. A. Smith found this method unsatisfactory and recommends the oxidation of sulphide of antimony by ...

Aug 24, 2016· "Antimony was a good test vehicle for the idea, but we could imagine doing something similar for much more common metals," Sadoway says. And while this demonstration used an ore that is a sulfide (metal combined with sulfur), "we see no reason why this approach couldn't be generalized to oxide feedstocks," which represent the other ...

ore (Sb 2S 3), but also occurs as oxide (Sb 2O 3), and as anti monides and sulphoantimonides of metals like lead, copper, zinc, silver, and gold [3]. Antimony is mainly used in the form of Sb 2O 3, as flame retardant in plastics, coatings, and electronics, due to its synergetic effect with halogenated

While their exact definition and listings tends to be less welldefined, many minor metals tend to be produced in smaller quantities than base metals, often as byproducts extracted from base metal ores.