Induration (drying and hardening) of iron ore pellets is an energyintensive feed preparation step for both the blast furnace and direct reduction routes to iron.

drying kiln iron ore

include iron scrap, reduced iron pellets and reduced iron briquettes. Sintered ore is made by partially melting and sintering coarse iron ore 1 to 3mm in size into products having a size of 15 to 30mm. The sintering process uses the combustion heat of coke breeze (fuel). Pellets are made from iron ore that is .

And the metallurgy chemical kiln is mainly applied in metallurgy industries, like, magnetizing roast of the weak magnetic iron ore in ironworks, oxidizing roast of the chromium and nickel ore, roast of the high aluminum bauxite in refractory material industry, roast of clinker and aluminum hydroxide in aluminum manufacturer, and roast of the chromium ore and chromium powder in chemical industry.

55kw Wet And Dry Process Cement Rotary Kiln Cement Plant, Steel Mill / Rotary Lime Kiln. ... 1500×4500 Ball Grinding Machine Mining Ball Mill for Gypsum Limestone Iron Ore. Industrial Drying Equipment. 1×10 Energy efficiency Industrial Drum Drying Equipment For Coal / Rotary Drum Dryer.

Iron Ore/Taconite HarbisonWalker International. Iron Ore/Taconite In the ironmaking process, the blast furnace or directreduced iron (DRI) plant will typically use iron ore pellets, which are created when iron ore fines are agglomerated and heated using a rotary kiln.

of Iron Ore Pellets during Up Draught Drying AnnaLena Ljung 1, T. Staffan Lundström 1 and Kent Tano 2 1 Division of Fluid Mechanics, Luleå University of Technology, SE 971 87, Luleå, Sweden

Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include:Cement, Lime, Refractories,Metakaolin, Titanium dioxide, Alumina, Vermiculite, Iron ore pellets

Brief Introduction of Rotary Kiln Rotary kiln (cement kiln) is used for making of cement clinker and there are dry and wet methods to make cement. Rotary kiln (metallurgy chemical) kiln is used for magnetic roasting of iron ore and oxidizing roasting of chrome and nickel in the steel factory.

Jul 29, 2010· The reduced iron ore SPONGE IRON with unburnt char from rotary kiln gets discharged into a Rotary Cooler. The heat will be dissipated indirectly by water spraying into the outside of Cooler Shell. The material gets cooled to around 1200C.

Iron ore pelletizing 3 Process flexibility There are two main processes for producing iron ore pellets The GrateKiln system and the straight grate system In the straight grate system a continuous parade of grate cars moves at the same speed though the drying induration and cooling zones Any change in one section effects the residence

In the present study, an improved numerical heat transfer model has been developed for a rotary kiln used for drying and preheating of wet iron ore. The present model includes radiation exchange among hot gas, refractory wall and the solid surface, transient conduction in the refractory wall, and mass and energy balances of the hot gas and the solids.

Jan 01, 2018· Coal ash, ironore pellet powder and mixed powder. In drying and preheating processes of pellet production, pellet powder formed from broken pellets is brought into rotary kiln with the unbroken pellets and then meets with coal ash which is generated by coal combustion.

TAIDA Iron Oxide Rotary Kiln can save a large number of your investment, so take advantage of this method can not only produce high quality iron oxide red pigment, also can get excellent benefits. Drying Equipment,Dryer Equipment Manufacturer,Industrial Drying Equipment,Drying Equipment Manufacturer

The kiln is inclined with horizontal at degree and it rotates with rpm. The feed is injected from the feed end of the kiln which consists of iron ore, coal and dolomite. Feed material moves gradually towards the discharge end as kiln rotates, from where sponge iron collects.

Metallurgy chemical kiln is widely used for magnetic roasting of poor iron ore and oxidizing roasting of chrome and nickel in the steel factory; backing highalumina mine in the refractory material factory; baking chamotte and alumina in the aluminum factory and .

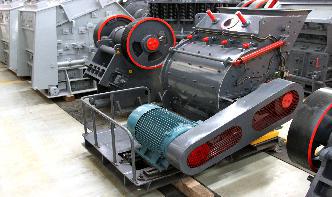

Rotary Kilns. Iron Ore Roasting Rotary Kiln for Sale. Savona Equipment is your supplier for new, used, and rebuilt ore roasting rotary kiln. There are two basic types of rotary kilns; direct fired and indirect fired. Rotary Kilns are a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process.

kiln furnace for drying gold ore kiln furnace high tech development A shuttle kiln is a batched firing furnace, it applies to small scale production of ceramic, porcelain, fire brick, and so on.

kiln iron–ore pellet induration process PDF Free Download Induration (drying and hardening) of iron ore pellets is an energyintensive feed preparation step for both the blast fu... Convective drying of an individual iron ore pellet ...

Virtual indurator: A tool for simulation of induration of wet iron ore pellets on a moving ... on a rotating disk or drum to produce wet pellets and induration on a moving grate to ..... carried out on a kiln used for iron ore pellets induration in China. ... of Gas Flow Distribution .