the rolls get deflected by high rolling forces. Elastic deformation of the mill takes place. If we use stiffer rolls, namely roll material of high stiffness or elastic constant, we could avoid mill spring. Normally elastic constant for mills may range from 1 to 4 GNm1. Roll elastic deformation may result in uneven sheet thickness across.

high cold rolling mill used

A tandem mill arrangement (H in the figure) has one stand behind the other and is used for highproduction rolling of almost all products. This continuous arrangement requires the construction of long rolling trains and buildings, but layouts can be shortened by a socalled semicontinuous mill, in which the workpiece is passed back and forth through a reversing mill before being sent through the rest of the .

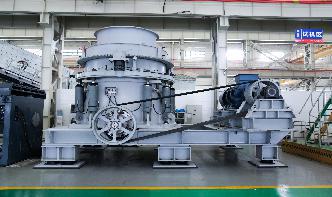

The cluster mill, or Sendzimir mill, uses a small work roll backed up by many other rolls. This extremely rigid setup is often used for cold rolling high strength material to a very thin width.

Slabs are the feed material for hot strip mills or plate mills and blooms are rolled to billets in a billet mill or large sections in a structural mill. The output from a strip mill is coiled and, subsequently, used as the feed for a cold rolling mill or used directly by fabricators.

Motors for Metal Rolling Mills. High strength of insulation required for special operating duty and steel mill environment will ensure long operating life. Static and dynamic strength analysis of stator, frame, rotor, shaft and bearings. Selection of appropriate forged steel shaft with high tensile strength.

used cold rolling mill trade offers directory and used cold rolling mill business offers list. Trade leads from used cold rolling mill Suppliers and used cold rolling mill buyers provided by

Four high tandem mills are generally used for aluminium and copper alloys. In order to achieve upto 90% reduction in thickness in cold rolling, a series of rolling mills may be used to share the total reduction. One important application of cold rolling is the removal of yield point from mild steel sheets using skin pass rolling [temper rolling].

The diameter of the 4high work rolls amounts to approximately 1:4 in relation to the barrel length. This type of rolling mill is mainly used in offline applications for cold rolling of soft and medium strip and for a wide range of strip widths, as well as for breakdown rolling in offline applications.

The RCM is the allrounder among cold rolling mills. Mainly used for rolling low carbon steels, it's also a great solution for advanced grades such as silicon steels. And, if you want to produce small to medium batch sizes, this mill type is a highly efficient option.

Sendzimir ZHigh® Mills were developed to combine the advantages of the Sendzimir clustertype rolling mill with those of the 4High. Revamp Existing Mill The ZHigh® concept permits the revamping of a classical 4High mill with a system that uses amuch smaller work roll.

May 10, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

Cold Rolling Mills for Wire Bars; Continuous Annealing Furnaces; Batch Annealing Furnaces; SawDeburrChamferPolish; Straightening Machines; Tube Bending Machines; PicklingLubricationDegreasing; Tube Coiling Machines; Centerless Grinder; Packing Weighing; Miscellaneous; Tube Welding Lines; Sheets Rolled Products. Hot Rolling Mills; Hot Metal Shears

In rolling mills, intermediate steel products are given their final shape and dimension in a series of shaping and finishing operations. Most of the slabs are heated in reheating furnaces and rolled into final shape in hot– or cold–rolling or finishing mills. While some products ( reinforcement bars, steel plates) only require hotrolling, some others may require both hot– and cold ...

This is a for sale ad about 6 Hi cold rolling mill ( 6 Hi mill). Its condition is used, second hand, surplus, or refurbished. EquipMatching Ad 336200

The heart of the temper mill is the cold rolling mill stand which produces the temper pass. It will include electric powered drive motors and speed reduction gearing suited to the process desired. The design of the rolling mill can be a 2high or 4high (even 6high in some cases). The mill stand can be work roll driven or back up roll driven.

FENN offers several standard Rolling Mill types; however custom mills can be designed to suit any application or production requirement. Standard Rolling Mill types include: Two High Generally used for hot or cold breakdown, rundown and finishing of bar, sheet or strip. A wide range of sizes with separating force capacities from 10,000 lbs. ( MT) to over 3,000,000 lbs. (1360 MT) are available.

Equipment Listings Rolling Mills. Input Gauge Range: 4mm •• Output Gauge Range: •• Max Speed: 135 M/min •• Max Tension: NA •• Max Load: 180 tons •• Max Coil Weight: 4500 kg •• Coil Dimension ID: 508mm ••... For Information... IEN# 118819 .

used cold rolling mill trade offers directory and used cold rolling mill business offers list. Trade leads from used cold rolling mill Suppliers and used cold rolling mill buyers provided by

Search for used rolling mill 4 high. Find , Stanat, , and Waterbury for sale on Machinio.

Oct 18, 2017· Next type of rolling mill is three high rolling mill. In this type of rolling mills, three rollers are used one over the other in a vertical line. We can pass the ingot between first two rollers ...

Jun 26, 2015· This reaction forms a mill scale or a flaky surface of iron oxides. The mill scale can affect the surface quality of the hot rolled steel if left alone. To remove the iron oxides the material is then sent through a mill scale cleanse. It is sprayed with high pressure water (much higher than your power washer at home). Rolling Mill and Stands

Multiroll cold mill stands are described using different terms depending on their type and manufacturer: 12 and 20 roll stand ZHigh® SHigh. Multiroll cold rolling mills are used to process high grade steel strip and nonferrous metal strip. In order to prevent whipping of the .