French Encaustic Cement Tile. French Encaustic cement tile are handmade from natural materials, each tile is unique in appearance. All colors shown are representational only and may vary slightly with each batch. Custom sizes finishes are subject to minimum quantity lead time. Stock LA Warehouse.

hydrophilic mill for cement industry

Mill Bits for Cement and Composite Plugs The Hurricane, Bear Claw, Chomp, and Aardvark are types of drill bits used for milling out cement, metal, composite and high pressure plugs. Hurricane Mill Bits are recommended for milling cement and composite plugs.

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo. In industrial countries, 80% or more of cement is delivered in bulk. Our raw mill has been widely used in the cement making plant. In a large number of customer feedback, we received a lot of enthusiasm and positive ...

Use of alternative fuels in cement industry. ... (XRF), optical microscopy in two series of raw mill, clinker and fuel samples with and without the use of TDF. Furthermore, the compressive ...

MasterRoc MP 320 supplied by BASF Construction Chemicals Iran is a Solventfree, low viscosity, hydrophilic grout for rock injection and consolidation of sandy and silty strata

Cement Ball Mill Sizing Explanation The Cement Grinding Office. This method only gives a rough and initial idea for sizing a cement ball mill. To go ahead, a deeper ... The wellknown Bond formula used is the following: .... In the cement industry, the dry process is always used except some old. installations ....

SOME PROPERTIES OF FIBERCEMENT COMPOSITES WITH SELECTED FIBERS Anais. Conferência Brasileira de Materiais e Tecnologias NãoConvencionais – Habitações e InfraEstrutura de Interesse Social – Brasil NOCMAT, Pirassununga, 29/10 a 03/11/2004. 35 effect of the different fiber content and types in the physical and mechanical performance of

API class H cement was used with watercement ratio of For all the samples % (By the weight of total, BWOT) of conductive filler (CF) was added to the slurry in order to enhance the piezoresistivity of the cement and to make it more sensing. The smart cement slurry was mixed with different percentage of 1, 2, 5 and 10% of HPR.

CemNet Training courses provide a thorough learning experience for cement industry personnel, with a wide range of features designed to accelerate full understanding of the complete manufacturing can learn 24hrs a day, 7 days a week over the course period at a time and pace that suits them. This cost effective training can lead to increased knowledge retention and a stronger ...

Cement grinding Vertical roller mills versus ball mills. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

Aug 07, 2019· Glass ionomer cement is a dental restorative material, used as a filling and luting material. It is based on the reaction between silicate glass and polyacrylic acid. It is a popular material because of its better aesthetic and the property to release fluoride ions which helps in preventing caries. Features of Glass Ionomer Cement. Low solubility

Due to the nature of cement production, cement kilns require temperatures of 2000°C in their main burner. Excellent conditions for waste derived fuels, they have become a standard fuel for many cement kilns around the world. But there is potential for this to grow fivefold. by Jan Theulen The ...

Brilliance at Work! Cement Lubrican Machine Fuchs Lubritech Some of the key machines in cement production are crushers, mills, kilns, and coolers. ... especially developed for the specific requirements of the Cement Industry. ....Ball though ball mills are gra dually being replaced by vertical.

Use of Hydrophobic and Hydrophilic Polyurethane s for Crack Injection Polyurethane s used in concrete repair to prevent water penetration through concrete cracks are said to be either hydrophobic or hydrophilic in behavior.

Emissions control is a hot topic in the cement industry. Cement plants are driven by throughput, but if they fail to comply with the new NESHAP (National Emission Standards for Hazardous Air Pollutants) regulations, production could be stopped immediately, introducing a slew of cost factors that affect plants' bottom line.

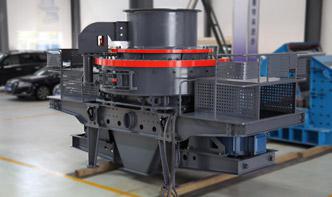

A cement mill is key equipment for recrushing the materials after they are primarily crushed. It is widely used in the dry type and wet type powder grinding of all kinds of ores and other grindable materials in cement, silicate product, new type building material, refractory, fertilizer, ferrous metal, and nonferrous metal beneficiation and glass and ceramic production industry.

Chemical, Mineral Cementitious Grouting PreInjection and PostInjection Technologies. Unexpected water ingress and poor ground conditions during mining and tunneling operations can cause significant problems for underground contractors.

Cement Blast Furnace Slag. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The xcoordinate indicates which product throughputs can be generated using the respective mills. The width of the fields is a measurement of the output factor.

Over the last decades, many vertical roller mills for cement grinding have been put into operation all over However, the cement industry must meet manifold requirements in terms of sustainable development. alternative fuels and raw materials, thermal and electrical energy efficiency, clinker substitution and new.

Cement Industry Solutions Brochure Cement Industry Solutions Brochure. Whitmore offers an extensive range of industrial lubrication products that are designed for the Cement Industry. Our products perform in the most adverse conditions and demanding environments.

SICEMENT – solutions for the next level of productivity Companies in the global cement industry are facing major challenges: If they are to improve productivity while simultaneously decreasing costs, they need highperformance products that are also energyefficient and .