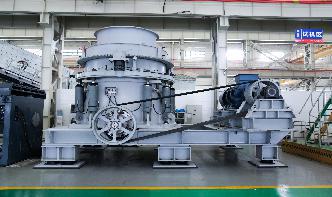

limestone crushing process in jaw crusher Crushing Plant Design and Layout Considerations Mining ... There are three main steps in designing a good crushing plant: process design, .....

what is limestone processing plant design layout

Product Layout. The product layout is the opposite of the process layout. Rather than have a specific section for each group of tools and supplies, the product layout is an assembly line. The required tools and supplies are located at each section of the assembly line, based on .

Production Plant Layout (1) Facility Layout Problem: design problem locations of activities dimensions configurations No overall algorithm exists Production Plant Layout (2) Reasons: new products changes in demand changes in product design new machines bottlenecks too large buffers too long transfer times Design Production Plant Layout (3) Goals (examples): minimal material handling costs ...

Facility Layout M 1 M 2 M 5 M 4 M 3 A typical manufacturing plant has a number of diverse activities interacting with each other. Thus, raw materials arrive at a shipping dock, they are unpacked and checked in a quality control area, they may then be processed through several processing areas, and finally the finished product again passes

In manufacturing engineering, process layout is a design for the floor plan of a plant which aims to improve efficiency by arranging equipment according to its function. The production line should ideally be designed to eliminate waste in material flows, inventory handling and management.

layout to demonstrate improvements gained by formal approaches to layout design. The definition of a plant layout problem is to find the best arrangement of physical facilities to provide an efficient operation (Hassan and Hogg, 1991). The layout affects the cost of material handling, lead time and throughput.

Jun 12, 2017· What is costs to build a plant will vary greatly from place to place and plant to plant: a very general rule of thumb is about 300/sq ft. Take a look at the feasibility studies below: there might be one for your region which will give you a more locally relevant number. Plant Design Guide; Meat Processing Feasibility Studies

Examples of plant layout and design Principles of plant layout and design will apply to most industrial situations. The following layout examples encompass a wide variety of facility characteristics, and of process characteristics. Readers, this is the most popular page on Thanks for your interest, and I hope you'll

−FGD process design −Fuel, limestone, makeup water • Treatment options: −Direct discharge −Volume reduction (evaporation,.) −Physical/chemical treatment • Suspended solids • pH adjustment • Heavy metals removal • COD removal Wastewater Treatment WPCA Wet FGD Seminar December 1, 2008

Designing an Effective Manufacturing Facility Layout For most manufacturing operations the goal is relatively simple: develop a lean manufacturing system to streamline production and ensure a smooth flow of work, material, and information.

An Applied Guide to Process and Plant Design is a guide to process plant design for both students and professional engineers. The book covers plant layout and the use of spreadsheet programmes and key drawings produced by professional engineers as aids to design; subjects which are usually learned on the job rather than in education.

Plant Layout is also known as facilities design. Plant layout constitutes planning of the amount of space required for all kind of activities in an industry,, equipment, machinery, furniture and fittings, offices, rest rooms, warehouses etc. The primary objective of plant layout is to minimize the movement of men and materials in the plant.

The information presented in this section is a general composite of best practices and current information about the design layout of your phosgene equipment for new construction, expansions and existing operations. It describes Plant Siting and Layout Guidelines with information relevant to the design and layout of new or revised facilities.

PLANT LAYOUT Plot layout: Wind direction 7080 m Main Process Auxiliary Processes Labs Offices Fence Regulations for fences and distance to equipment. Auxiliary processes: Power generation, cooling water, pumps, cooling towers, compressors, boilers, control equipment air. Personnel space should be upwind. Wind conditions should aid

Nov 21, 2018· The product layout approach involves setting up the production facilities around the steps involved in manufacturing the product. The product goes from one step to another as it is manufactured. This is the typical assembly line approach. For example, in the manufacturing process of a car, the car body goes from one stage of production to the next.

Mar 30, 2012· Traditionally, plant layout has focused on linear lines and processbased departments. But, assembly lines have changed dramatically in recent years due to trends such as justintime delivery and parts sequencing. There are nine common line layout .