Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefication, construction materials, chemical industry, etc, it has two ore grinding ways: dry way and wet way. According to discharge type of finished powder, it can be divided into two kinds: grid type and overflow type.

mill pin crusher ball mill wet grinding bal

The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding bowl respectively the mortar. The grinding can be performed dry or wet. In addition to comminution Ball Mills are also the ideal and reliable lab assistants for mixing and homogenising.

Powders of extremely high fineness can be produced with ball mills and agitated media mills. When wet mills are used, fineness values in the submicron range (>1 µm) can be achieved. These mills are equipped with grinding media (balls, grinding beads) for the grinding process.

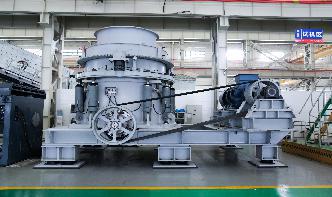

Ball mill, Grinder mill, crusher, Grinding Mill, Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable ...

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

General Kinematics VIBRADRUM® Grinding Mills are proven in dozens of milling applications in the mining and mineral industries.. Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills. New processes such as micron grinding and mechanochemical grinding give our ...

On top of this, many companies treat different parts of their mining operations as independent units. It's not uncommon for a large mine to have independent planners looking after blasting, primary crusher throughput, secondary and ball mill grinding as well as the concentration plant.

Ball Mills Manufacturer Ball Mill Working Principle. A ball mill is a type of grinding mill, it is an aggregate for grinding and crushing (grinder) of hard materials that has the same goal as other grinding machinery and crushing mills are used for crushing and mixing of raw materials. While rotating, the grinding media (balls, beads, pulps, etc.) and the raw material rotate ...

Working Principle. Principle of overflow ball mill: the main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder.

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

ball mill is one of energy saving mills developed by our company, which is easy to start and saves 2030% energy. It is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

Wholesale Various High Quality Gold Ball Mill For Sale . using volume method ball mill for more crushing ball mill size for more crushing and less Ball mill Wikipedia A ball mill is a type of grinder used to grind Less wear takes place in rubber lined mills.

Cement ball mill can not only dry production but also wet production, grinding and drying at the same time. Cement mill is mainly used in building materials, metallurgy, power and chemical industries, grinding all kinds of cement clinker and other materials.

ECUTEC's Taurus is the latest technology in Mills using Grinding Media for comminution.. A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill. These grinding media are crushing and grinding fresh product due to impact and friction.

Ball mill manufactured by with the most advanced ball mill working principle is widely used in industrial powder grinding. cement mill and cement ball mill are highly praised by users at .

Energysaving Dolomite Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

Ball Mill Liner Function. Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to improve the mill grinding efficiency, increase ...

May 18, 2017· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of diffe...

Wet Pan Mill Working Principle Main parts of wet pan mill are frame, basin, grinding roller, grinding base, speed reducers, motor and etc. Firstly, motor transmits power to speed reducer, then center driving shaft transmits into horizontal shaft, finally grinding roller will move counterclockwise and material will be ground into fine particle in the wet pan mill.

Planetary Ball Mill; Laboratory Jet Mill; Electric Mortar Grinder; Agate Products; Jar Mill; MidRange Grinding. Dish And Puck Mills; Jaw Crushers; Cross Beater Mill; Grindomix; Cutting Mill; Polymix / Micro Hammer Cutter Mill; Disc Mills; Coarse Grinding. Hammer Mill; LaMilpa Mill; RoHS Grinding and Sample Prep; Wet Milling. Bead Mills. DYNO ...

Stedman Machine Company manufactures highquality, efficient cage mill crushers with multiple row capacities (2, 4 6) for size reductions! Stedman industrial pulverizing mills are utilized by a variety of industries including aggregates and mining. Our cage mill machines are available in various sizes with feed, capacity, and horsepower options.

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30' x 41' . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives. Our mills incorporate many of the qualities which have made the Marcy name famous since 1913.