process, ensuring a safe work environment, rectifying problems and facilitating output changes. Application of the Unit Application of the unit This unit of competency applies to operators who are responsible for preparing materials for grinding; grinding materials and distributing ground materials. This competency is typically performed by operators

describe the process of manufacturing aggregates grinding

Nov 01, 2013· Manufacturing process MATERIAL CUTTING TO LENGTH OF MATERIAL BILLETS HEATING HOT FORGING 9 10. PLERCING TRIMMING SHOT BLASTING /SHOT PEENING DEBURRING MACHINING MACHINING OF TOP SURFACE GRINDING THE SIDE FACES DRILLING THE PISTON END BROACHING OF CRANK AND PISTON ROD DRILLING OF BOLT HOLE DRILLING OF HOLE MACHINING .

In order to predict accurately the residual stresses generated in the ground workpiece materials, reliable modeling is always required. It is a wellknown fact that the grinding process is rather ...

Whether traditional or new manufacturing processes are involved, none of the available technologies make it possible to produce component surface finishes in the required quality. Process steps such as deburring, rounding and cleaning, as well as targeted functional .

Cleaning. In between product runs, all of the equipment used in our manufacturing process is taken apart, cleaned, and sanitized. Adenosine triphosphate (ATP) testing is used to validate effectiveness of the equipmentcleaning process. In addition, the surrounding production suite, including floors, walls, and vent covers, is cleaned.

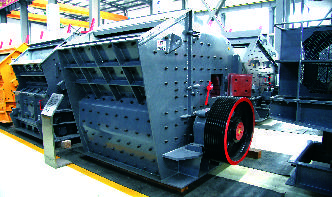

manufacturing, and coated abrasive product manufacturing. Abrasive grain manufacturers produce materials for use by the other abrasives manufacturers to make abrasive products. Bonded abrasives manufacturing is very diversified and includes the production of grinding stones and wheels, cutoff saws for masonry and metals, and other products.

describe the process of manufacturing of aggregates Gold Aggregates manufacturing process PPT | Gulin Solutions Describe differences between aggregate plans » Learn More Aggregate/Production Planning The output of the aggregate planning is a production plan or an It also gives workers time for problem solving and process

The Manufacturing Process Most grinding wheels are manufactured by the coldpress method, in which a mixture of components is pressed into shape at room temperature. The details of processes vary considerably depending upon the type of wheel and the practices of individual companies.

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of to the process during the finish grinding operations described below. These materials, also excavated Process flow diagram for portland cement . Cement Manufacturing Process Flow Chart

GRINDING MACHINES Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel. When ... ABRASIVE MATERIALS The abrasive grains are the cutting took of a grinding wheel. They actually cut small pieces or chips off the work as the

grinding operation. 13. Describe how to grind nonferrous metals successfully, and explain what potential problems to anticipate and check for within the grinding operation. 14. Describe how knowledge of grinding wheel materials will help to ensure high quality, high productivity, and low scrap rates. 15.

The following data, in physical units, describe a grinding process for January: Work in process, beginning 18,600 Started during current period 189,000 To account for 207,600 Spoiled units 12,600 Good units completed and transferred out 170,000 Work in process, ending 25,000 Accounted for 207,600 Required: Inspection occurs at the completion stage.

A process system is likely to be used in the shipbuilding industry. A process system is used primarily in service companies. A process system produces the unit cost of a product by specific identification. A process system is appropriate to use when a company produces homogeneous, low cost products

The process equipment may belong to the groups of mechanical, thermal, chemical, photonic, and electrical equipment, as well as to combinations of the groups. Tooling elements include cutting tools, grinding media, dies, molds, forms, patterns, electrodes, and lasers.

MANUFACTURING PROCESS OF AUTOMATED BRICK. The first stage in the manufacturing process of the soil clay brick start with the selection of the raw material. RAW MATERIAL. The main raw material in brick making is clay and it is one of the most abundant natural mineral materials on the planet.

Machining in the Manufacturing Sequence Generally performed after other manufacturing processes, such as casting, forging, and bar drawing Other processes create the general shape of the starting work part Machining provides the final shape, dimensions, finish, and special geometric details that other processes cannot create

May 22, 2017· CNC machining is a manufacturing process in which preprogrammed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, threedimensional cutting tasks can be accomplished in a single set of prompts.

Dec 03, 2013· To further understand ID grinding quills, it's necessary to know the different materials used in manufacturing ID grinding quills and the types of process for their manufacture. The most common ones are listed here. The 4 Most Common ID Grinding Quill Styles

Dec 17, 2018· Manufacturing Process. When a manufacturing company begins production of a new material, it has a choice as to the manufacturing process it uses. The type of process depends on the facility, the staff, and the information systems available. Each process has its advantages and some are best at certain tasks, for example,...

Journal of Manufacturing and Materials Processing (ISSN ) is an international peerreviewed open access journal on the scientific fundamentals and engineering methodologies of manufacturing and materials processing published quarterly online by MDPI.. Open Access free for readers, with article processing charges () paid by authors or their institutions.

Methods of Manufacturing Process of Cement. 1. Dry Process of Manufacture of Cement. (i) Treatment of Raw Materials: (ii) Burning or Calcination of the Dry mix: (iii) Grinding of Clinker: (iv) Packing and Storage of Cement: 2. Wet Process of Manufacturing of Cement.

Fundamental grinding parameters, such as the effective grain density, grain spacings, chip depths, and chip areas, are employed to describe the grainworkpiece interactions. The grinding process is studied under a systematic variation of table speed, wheel depth of cut, and grain apex angle.

Magnet Manufacturing Process There are several processes for making magnets, but the most common method is called Powder Metallurgy. In this process, a suitable composition is pulverized into fine powder, compacted and heated to cause densification via "liquid phase sintering".