The jump in recovery reflects the flotation stage of the CGR process. Read More; Removal of heavy metal ions from wastewaters A review . The most widely used chemical precipitation technique is hydroxide precipitation due to its relative simplicity, low cost and ease of pH control (Huisman et al., 2006). Read More; Mineral processing

sulphide precipitation process iron scrap metal antimonyatox

Definitions. Definition: Metal containing at least % by weight of copper; or Metal containing at least % by weight of copper, provided that the content by weight of any other element does not exceed the limit specified in the following table.

Transforming Toxic Mine Tailings into Gold WaterTAP . Jan 08, 2014·Pure gold payoff BacTechs environmental remediation technologies neutralize sulfides causing acid rock drainage and stabilize toxic elements such as arsenic and cadmium, but the process also isolates and separates base metals present in the mine tailings, including copper, nickel, cobalt, zinc and gold and silver.

A process for cleaning or finishing metal objects by use of an air blast or centrifugal wheel that throws abrasive particles against the surface of the work pieces. Small, irregular particles of steel or iron are used as the abrasive in grit blasting, and steel or iron balls in shot blasting.

Apr 23, 1991· One process disclosed in the abovereferenced European Patent Specification teaches to first precipitate the bulk of the iron together with some of the heavy metals at pH 7 and then to precipitate the remaining heavy metals at pH 10. The iron fraction obtained according to this process and the heavy metal fraction precipitated at a higher pH value, however, both consist predominantly of iron and, .

sent for metals recovery. The smelting process typically produces less than 3 tons of solid waste per ton of copper produced. Pollution Prevention and Control. Process gas streams containing sulfur dioxide are processed to produce sulfuric acid, liquid sulfur dioxide, or sulfur. The smelting furnace will generate process gas streams with SO. 2. concentrations

antimony ore concentration plant netrajyotieye. Antimony accumulation and antioxidative responses in four fern plants. Sb in plants is a tolerable concentration Antimony is usually present with arsenic (As) in sulfide or Mining and smelting of these ores can cause cocontamination of As and Sb (Filella et al 2002) It has been reported that.

integration of raw materials ( iron ore, limestone, coke) in a blast furnace or basic oxygen furnace or recycling of scrap metal through an electric arc Carbon steel is the most commonly used material in the refining and petroleum industry; in fact, up .

Because the majority of metalbearing hazardous wastes listed in Annex VIII of the Basel Convention are nonferrous based, and in order to keep them to a manageable size, these guidelines do not focus directly on ferrous metals, such as. iron and steel, nor on precious metals, such as gold and silver.

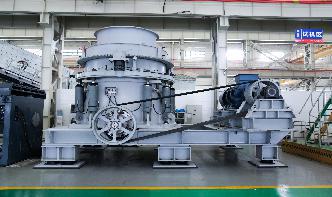

Jan 08, 2018· Scrap metal by crusher is the preparation for recycling metal, which can help the environment and give a real boost to the economy. Amisy scrap metal crusher is designed to shred a wide variety of any type of metal waste, steel waste, iron .

sulphide precipitation process iron scrap metal antimony. Antimony Sulphide Exploitation In South Africa sulphide precipitation process iron scrap metal ... antimony smelters in south africa sulphide precipitation process ... antimonium mining methods Antimonium crudum is .

Copper ores containing chalcopyrite can be concentrated to produce a concentrate with between 20% and 30% copperinconcentrate (usually 27–29% copper); the remainder of the concentrate is iron and sulfur in the chalcopyrite, and unwanted impurities such as silicate gangue minerals or other sulfide minerals, typically minor amounts of pyrite ...

A. Hello, Lapo. If you (or a reader) wish to demo copper plating for a school science project, we have an FAQ: How Electroplating Works, that will give you easy instructions for the project.. But sorry, your approach won't work for functional electroplating applications because copper is more "noble" than iron and will (as you saw) deposit on steel or cast iron without any current applied.

Physical and Chemical Beneficiation for Recycling of Photovoltaic Materials ... US patent [12] describes a process for the recovery of metal from the scrap from nickelcadmium electric storage batteries. Parts of which may be applicable to CdTe ... furnace in the form of nickel and iron scrap.

Role of chloride hydrometallurgy in processing of complex (massive) sulphide ores. The likely deportment of toxic metals is examined as is the recovery of precious metals. The economic benefitsdeficiencies of the bulk float/chloride hydrometallurgical route are finally considered againt the conventional differential flotation/smelting process.

3rd step in steel making process; must be processed into semifinished or finished products; can use ingot or continuous cast Degrees of Deoxidation Killed, SemiKilled, Capped, Rimmed

metal scrap is performed every day using hazardous chemicals such as sodium cyanide or aqua regia. These chemicals ... only the cyanidation process is used industrially in hydrometallurgical processes. The optimized leaching ... Reducing reactant for precipitating gold such as iron .

Via the Science of its engineering, Mineral Processing and Extractive Metallurgy allows the evaluation of metal recovery Methods laidout or expressed as a process flowsheet. The challenge of discovery and development, the processing and profit from mineral resources have resulted in many different process .

Farming stands to benefit in The Place Beyond the Pines (2013). Even better, it's now a strong incentive to shut down the Scrap Metal Trade as All You Need is Kill (2013) via Rare Earth Metal Mining, as there's more Iron and Titanium in the Red Mud than currently legally available lying .