Jun 10, 2018· The remaining ore is then heated in a huge furnace called a smelter, which burns off some of the remaining impurities and leaves a material called copper matte, which is at least 50 percent copper. A second heating process follows in which the copper matte is heated with silica and air to remove more waste, leaving a very refined material ...

copper ore production dry process wet process html

Manganese Ore Magnetic Separation Production Line; Cu Pb Zn Dressing Process; Kaolin Mining Process; Titanium Mining Process; Chrome Ore Mining Process; Magnetite Separation Production Line; Gold Cip Production Line; Navigation Home . Read More ... copper ore mining and quarry equipment india; View more. Designed Capacity Reached.

May 22, 2017 The attraction of semiautogenous grinding in copper operations is that they can accommodate ores that are hard or soft, wet or dry, sticky or >> Get Price; Copper Ore Grinding Machine, Copper Mining Process Plant. Therefore, copper ore investors should adopt highquality copper ore grinding machine to improve the mining efficiency.

Copper ore typically contains less that 1% copper in the form of sulphide minerals. Once the ore is delivered above the ground, it is crushed and ground to a powdery fineness and then concentrated for further processing. In the concentration process, ground ore is slurried with water, chemical reagents are added and air is blown through the slurry.

Wet milling may be a more intensive process, but it can reduce a product into more components, and into finer particles in the micron submicron (or nanometer) particle size range, allowing for the production of a greater variety of byproducts and improved physical properties.

Union Process offers the most comprehensive line of Production Attritors in the world. Choose from Wet or Dry Grinding and Batch, Circulation or Continuous Processing. Contact Union Process for help in determining which Attritor is right for your specific application.

Electricity used in the production of equipment, parts, construction materials (such as cement and steel), consumables (such as balls, rods, and linings), anode paste, fuels, reductants, and other reagents manufactured offsite and transferred to or purchased by a facility are not included in the estimates.

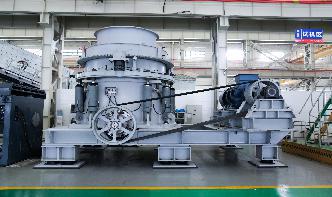

Crusher For Sale openpit crusher plant,openpit processing, Copper Ore Production Dry Process Wet Process 53 Views The Zenith is the professional mining equipments manufacturer in the world, located in China,India, along with, More Info; BENEFICIATION OF IRON ORE ethesis.

LUM Series Superfine Vertical Roller Grinding Mill is widely used to process the superfine dry powder heavy industry with more than 30 years manufacturing experience of four generations of grinding mills, introduced the German advanced technology, designed and developed the new Superfine Grinding Mill LUM Series Superfine Vertical Roller Grinding Mill .

Once oil sands feed is received from the mine and broken down on the dryside of OPP, the ore is then mixed with hot/warm water to produce a dense slurry. The technology used to slurry the oil sands varies between the operator, but the objective of OPPWet is the same: produce an aerated pumpable slurry and remove any oversized material that may damage downstream equipment.

beneficiation iron ore washing. Kolkata iron ore dry process beneficiation. list of iron ore beneficiation plants in Nigeria, For clayey Ironmagnetite quartzite, ore washing process and drytype magnetic, Get More Info methods for iron ore beneficiation Grinding Mill China iron ore beneficiation method Besiktas JK Iron ore.

of drychemical structuring by means of plasma etching, wetchemical etching methods have to be used for this purpose, if necessary, in combination with a subsequent fortifi cation by electroplating. Copper Etching Copper is etched by (also diluted) nitric acid as well as saturated 30% Fe (Cl) 3 solution. Mixtures of NH 4 OH and H 2 O 2 etch copper as well.

Weld Range Iron Ore PreFeasibility Study Sinosteel Midwest. Sep 1, 2008 The process entails sizing the 1mm fines material via a wet plant, using 1 mm + 65 micron Dewatering screen product moisture % 20.

Ferro manganese fire wet ball mill icchmt2017g ball milling the method of producing manganese metal powder ul 16 2014 t can be both used in the dry ground and wet grinding. Ferromanganese Ore Iron Ore Grinding Machine. Wet ball mill wheels in ore dressing zinc ore beneficiation process for silver in papua new guinea new type copper iron ore ore ...

process grinds the powder materials by impact/collision attrition. • Milling can be dry milling or wet milling. In dry milling, about 25 vol% of powder is added along with about 1 wt% of a lubricant such as stearic or oleic acid. For wet milling, 3040 vol% of powder with 1 wt% of dispersing agent such as water, alcohol or hexane is employed.

iron ore wet milling process involved . iron ore fines grinding process oerp in The process of iron ore mining, the first step is first ore is crushed and transported back to the OPFs for grinding and the wet scrubber removes the waste from the ore and categorizes it into oversize, midsize and undersized.

Brief introduction to copper ore beneficiation plant. As a famous Chinese copper ore separation plant manufacturer, our company's copper ore separation process, also called copper ore processing line, mainly adopts the advanced flotation separation technology. So sometimes it's also called the flotation copper ore beneficiation plant.

Chrome Ore Mining Process EPC Xinhai EPC provides services of sample test, mine design, equipment manufacture, etc. for clients, and solves the common problems in plant construction such as budget overrun,disputes of the manufacturers...

Copper ore processing in South America: the primary ore grinding stage consists of four POLYCOM® highpressure grinding rolls, while four wet process ball mills perform the final grinding. Example configuration for a thirdgeneration grinding circuit.

Grinding By Wet Vs Dry In Iron Ore intramedc2c. wet grinding iron ore . grinding by wet vs dry in iron ore villasovaggioit. grinding by wet vs dry in iron ore absolutemachineu wet grinding process iron ore,wet milling process iron ore 25 Mar 2014, iron ore mining capacity taken into operation in 2007 reached almost, wet vs dry iron.

Oct 02, 2015· In this process, the materials go through screens, which separate them in line with standard product specifications. This is one of the most important production stages: screen classification. In wet ore processing, this classification uses water to remove impurities that harm the products' final quality.

Dry heat sterilization is used to decontaminate objects and spaces. This lesson will discuss the meaning of, process, and validation of dry heat sterilization.

The main Carajás plant, Plant 1, is in the process of conversion to natural moisture: of the 17 plant processing lines, 11 are already dry and the remaining six wet lines will be converted by 2022. Serra Leste's treatment plants, in Curionópolis, and S11D, in Canaã dos Carajás, also do not use water in ore treatment, according to Vale.