Mechanical Alloying or High Energy Milling: Mechanical alloying was originally invented as a method to manufacture oxide dispersion strengthened nickel alloys It is a high energy ball milling process, where alloying is the result of the repeated fracture and cold welding of the component particles.

which alloy is used for making ball mill

ball alloy steel for ball mill mdietician Ball screws are very similar to ball bearings in that they generally use either chrome steel or type 440C hard stainless steel. A peculiarity of ball screws is that they typically have a load ball and the next ball is a .001inch undersized spacer ball, and so on.

ISO 9002 manufacturer of balls for use in mills such as ball mills, paint mills, pebble mills. Balls are manufactured from materials including 52100 chrome steel, C1010 C1020 carbon steels, tungsten carbide steel grades of C1, C2, 3100, stainless steel grades 302, 304, 316. JIT delivery drop shipment in neutral packaging available.

Corrosion and abrasion resistant, tough and durable, NITRONIC 30 is the stainless steel for your abrasive needs. Ball mill tests have shown that many application standards, such as AR 500 suffer six to seven times as much metal loss as NITRONIC 30. Economical, .

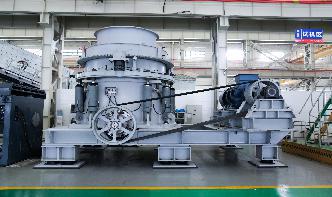

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying .

ball milling alloy. Structural and magnetic evolution of ball milled nanocrystalline Fe ... Structural and magnetic evolution of ball milled nanocrystalline Fe50 at.% Alalloy. ... HighEnergy Ball Milling Parameters in Production of ... Springer. in Production of Nanocrystalline Al Alloys. Alloying of elemental blends achievedthrough high ...

Sep 18, 2018· White metal is used to cast bearing surfaces, and also contains other metals to increase its hardness and wear resistance, and are also used to make cheap cutlery which can be silver plated. The bestknown bearing alloy is Babbitt.

Chromium alloy is the main composition of casting steel ball with diameter of 6 mm to 140 mm. According to different chromium content, the grinding ball can be divided into three kinds, namely low, medium and high chromium balls. The hardness of relevant balls are HRC≥45, HRC≥50 and HRC≥58 respectively, with diameter of 6 mm to 140 mm.

making process of silcomagnese alloy stone crushing machine projectmaking process of silcomagnese alloy ShangHai ( making process of silcomagnese alloy ) are a professional production of stone crushing machine.. making process of silcomagnese alloy Sales and Widely used in Europe, South America, Africa, East Asia and Asia region.

Ball Mill Process Lead pigs, or ingots are charged with air into a ball mill. Frictional head generated by the tumbling lead ingots initiates and oxidation reaction. Oxygen in the air, assisted by the heat of the tumbling lead, reacts with the lead to produce lead oxide.

Shell liners. We offer many choices in design and alloys for all popular mills, ranging from traditional wave styles to step liners, classifying liners and SAG mill liners. Trunnion liners. Not many foundries are capable of making trunnion liners.

Sep 18, 2007· Rating Newest Oldest. Best Answer: "Nonsparking", "sparkresistant" or "sparkproof" tools are names given to tools made of metals such as brass, bronze, Monel metal (coppernickel alloy), copperaluminum alloys (aluminum bronze), copperberyllium alloys (beryllium bronze), and titanium.

The chemical composition of AA6013 T6 aluminium alloy, which is used in present study was given in Table 1. The chips were extracted under commercial coolant by CNC milling from 10 mm thick plate with 2 mm depth of cut. ... Consequently, efficiency of ball mill is lower than the efficiency of cryogenic and disc type mills.

Nov 24, 2018· Aluminum alloy is the most widely used alloy at present. Properties of Aluminum based Alloys Aluminumbased alloys have low density but high strength, close to or higher than highquality steel, good plasticity, and can be processed into various profiles.