In cement mill, high torque at low speed (3 RPM) is normally obtained using. (a) Compound DC motors (b) VFD Induction Motor with gear arrangement. In power plant, the coal pulverisation plant / cement pulverisation plants, the low speed high torque is obtained using Eddy Current Coupling.

increase speed cement mill

Cement Additives Division 1 Improvement of cement performances through the use of grinding aids in vertical roller mill 'Arcangelo, – Mapei SpA, Milan, Italy Abstract Due to the stringent requirement of energy saving, the use of vertical roller mills for cement grinding is now common.

Shanghai Zenith Mining and Construction Machinery Co., Ltd. is a hitech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices.

Heavy feed rates are more suitable for HSS and cobalt tools. Carbide end mills, which can be run 23X faster than HSS, are best for maximizing speed and tool life. CarbideTipped: Offering some of the advantages of solid carbide tooling, carbide is brazed to the cutting edges of steel tool bodies.

TIle mill was drivenby an electric motor, and the averaGe mill speed was revolutions per lninute. The clinker charge consisted of 1000 grams or pounds of clinker. This is a weight r~tio of balls to charge of to 1. The ball and clirlker charge used, as well as the mill s~eed, had already been established as .

Spindle Speeders, Speed Increasers and High Speed Attachments can be the perfect cure for a problem you'll encounter surprisingly often. As I will show in a moment, they can increase your machine's throughput by 5x or more in the right circumstances, so they're well worth checking into.

on mill dimensions, the type of the mill (overflow or grate discharge), the speed of rotation, the mill loading, the final product size required from a given feed size (coefficient of reduction), the work index of the material, the mill shaft power and the specific gravity of the material. These parameters are thoroughly studied in

Properties of the major cement minerals About 9095% of a Portland cement is comprised of the four main cement minerals, which are C 3 S, C 2 S, C 3 A, and C 4 AF, with the remainder consisting of calcium sulfate, alkali sulfates, unreacted (free) CaO, MgO, and other minor constituents left over from the clinkering and grinding steps.

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill .

Hydration products. The products of the reaction between cement and water are termed "hydration products." In concrete (or mortar or other cementitious materials) there are typically four main types: Calcium silicate hydrate: this is the main reaction product and is the main source of concrete strength. It is often abbreviated, using cement chemists' notation, to "CSH," the dashes indicating ...

Grinding is the required powdering or pulverizing process when customers have a strict demand on final size. ZENITH can provide proper grinding equipment and solutions for different applications, such as XZM Series Ultrafine Grinding Mill whose output size can reach 2500mesh (5um)...

Cement mills are faster and more durable when cutting steel, as compared with a steeltooth bit, so they are recommended for any operation with steeltoothbit alternatives. These milling tools are available from 3 1/2 to 17 1/2 in, with fishing necks from 2 7/8 to 9 1/2 in.

Cement FingerPrint specifically designed to help customers sustain high performance. Cement FingerPrint provides a plant area benchmark, together with a set of recommendations aimed to increase the plant performance and its energy efficiency. Once the customer has implemented these recommendations, we have to

The power ingesting of a grinding process is 5060% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

When the SFM constant is known for a specific material, the formulas below can be used to determine spindle speed for milling various materials. SFM = RPM X .

Oct 17, 2018· By measuring the noise levels within the mill, you can adjust the mill speed to compensate and bring things back in line, resulting in more efficient grinding and energy usage. We also run into situations where a plant is relying too heavily on rules of thumb or .

Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

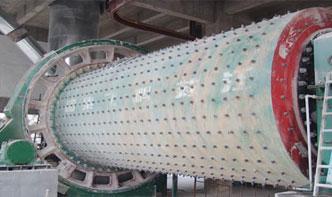

The theoretical data show that when the specification and rotating speed of the ball mill are fixed, when the filling rate (Φ) is less than 50%, the production capacity of the ball mill will increase with the increase of the filling rate (the filling rate of the general ball mill is 40 ≤ 50%, the high value of the lattice ball mill .

Bag filters used for the coal mill rank as one of the highest fire and explosion hazards in cement plants, due to the small particle size of the crushed coal. 3) Electrostatic Precipitators Buildup of explosive mixtures like finely dispersed coal dust in air, or carbon monoxide in air can result in an explosion hazard in Electrostatic ...

Fans in Cement Plants. Typical fan arrangement ofFans in Cement Plants. Fans in cement plants are typically centrifugal fan types (single or double flow). The blade design can be either a profiled shape or with single thickness plate blades. In most times, variable speed systems are used. Production scheme of a cement plant. (typical) Raw Mill ...