Aug 11, 2019· The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grinding. Some of the main ingredients used to make cement include limestone, clay ...

process of making cement additive

Make all of your concrete glow in the dark, make all of your old or new concrete glow in the dark. Glow in the dark concrete sealer additive can be used in the concrete sealer of your choice. Make your concrete sidewalks glow in the dark, concrete driveway can glow in the dark, concrete pavers and stepping stones can glow in the dark, concrete retaining walls can glow in the dark, glow in the ...

Process Crude petroleum is separated into its various fractions through a distillation process at the oil refinery. After separation, these fractions are further refined into other products which include asphalt, paraffin, gasoline, naphtha, lubricating oil, kerosene, and diesel oil.

Jul 14, 2015· Mechanical additives, such as soil cement, mechanically alter the soil by adding a quantity of a material that has the engineering characteristics to upgrade the loadbearing capacity of the ...

May 23, 2016· That's one of the great things about this process, actually. View in gallery. When you've reached a point that you're satisfied with the faux marble appearance of your concrete countertop (remember, everyone's preferences for veining are different – go with what YOU like), it's time to .

ARTICLES / Cement Based Tile Adhesive Formulations | Manufacturing Process Cement based and white tile adhesive contains white cement, silica sand using for filler,talc using for filler,calcite using for filler, starch ether using for holding water, methyl cellulose or hydroxyethyl cellulose using for thickness of mixture and etc.

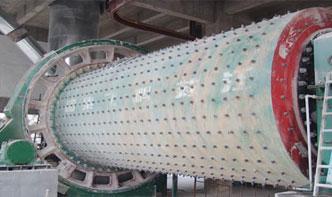

Aug 27, 2015· Cement Manufacturing Process. The entire operation of the plant is controlled centrally in a single control room and the plant employs minimum of manpower. The modern plants have also taken adequate care to prevent the environmental pollution and dust nuisance to its surrounding areas. The cement mills have electrostatic precipitators (ESP)...

SEALERS, ADDITIVES CLEANERS. Concrete Bonding Adhesive. QUIKRETE® Concrete Bonding Adhesive (No. 9902) permanently bonds new concrete, plaster, and stucco to existing concrete, plaster, and stucco. Eliminates the need for roughing the surface before the application. Exceeds the performance requirements of ASTM C 1059 Type I and II.

Traditionally, aerated concrete is autoclaved in order to achieve the high compressive strength necessary for structural use. While the high temperatures and pressures from the autoclaving process give rise to crystallization and thus high compressive strength, the process is extremely energy intensive.

Carbon dioxide (CO2) is a by product of a chemical conversion process used in the production of clinker, a component of cement, in which limestone (CaCO3) is converted to lime (CaO). CO2 is also emitted during cement production by fossil fuel combustion and is accounted for elsewhere.

The dry materials are mixed first. Water is added to the dry mix. Do not add too much water; the drier the mix, the stronger the final product. (Excess water stays trapped in the cured cement.) How wet to make the mi x is a function of the process: casting in a mold will need a wetter mix that slumps into place.

Concrete coloring using pigments is a simple process, accomplished by adding the pigments directly to the concrete mix prior to pouring. Pigments are available in liquid form or in "mixready" dissolvable bags. In both cases, the pigments are placed in the mixer with the other concrete ingredients. The range of colors available is typically confined to "earthy" variants of browns and tans, although greens, blues .

Water reducers, retarders, and superplasticizers are admixtures for concrete, which are added in order to reduce the water content in a mixture or to slow the setting rate of the concrete while retaining the flowing properties of a concrete mixture. Admixtures are used to modify the properties of concrete or mortar to make them more suitable to work by hand or for other purposes such as saving mechanical .

Apr 03, 1990· The invention relates to a process of making cement clinker and to an apparatus for performing said process. The process of making cement clinker may be subdivided into three different steps. In the first step, the finely ground raw material is heated to about 600° C.

Nov 27, 2011· PVA Additives... good or bad? Hi All ... Introducing an acid negates that process to some extent, preventing the cement or conrete from binding all the water it needs to harden properly. It is hydrolysis which gives cement and concrete products strength, and holds them together. Without this process, it would merely be the powder you started with.

Manufacturing Process White Cement At JK White Cement Works, Gotan we use technical expertise from Co. from Denmark and state of the art technology with continuous online quality control by micro processors and Xrays to ensure that only the purest White Cement is produced.

process of making cement additive. copper slag as additive in cement making process of making construction sand from copper slag . copper slag as additive in cement making « gravel crusher sale. copper slag as additive in cement making Get Price; grinding additive process description in cement .

Sep 14, 2018· Dry process These are two different processes of manufacturing cement. wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powder like the processes ar...

Feb 06, 2014· What you are describing is called High Early Strength Concrete. There are a number of ways to achieve this. Using a f'c=4,000psi concrete mix as a baseline, you could * Use a higher strength mix, like f'c=8,000psi. Concretes cure at different ra...

Rapidhardening hydraulic cement is manufactured with similar raw materials, equipment, and processes used to make portland cement, but that is where the similarities end. The chemistry of rapidhardening hydraulic cement, which differs from portland cement, is composed primarily of hydraulic tetracalcium trialuminate sulphate (CSA) and dicalcium silicate (C2S).

To make the process economic, microbial additive can be prepared by growing cells using industrial by products such as lactose mother liquor, corn steep liquor as nutrient sources. 4. Microbial additive can enhance the durability of bricks by reducing their permeability and increasing compressive strength.

You can review the whole cementmaking process here. Steps to Make the Homemade Survival Cement Step 1: Find a Source of Mud. What we have here is a natural mortar recipe for when you are making homemade cement from scratch. To make this homemade soil cement, you .

If your making your own mix using dry mix concrete requiring cement and water, and your making a mix ratio of 5:1, then you divide 108 by 6 = 18. therefore: 18x20kg bags of cement to 1800kgs of ...