CE approved factory price dry type grinding machine cement ball mill, US 2,850 9,850 / Unit, New, vibrating ball mill, AC from Xinxiang First Vibration Machinery Factory Co., .

cement ball mill production cost structure

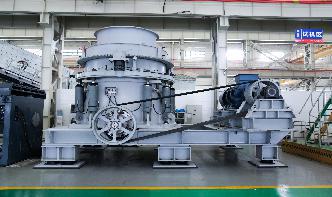

Production Introduction. Ball mill is the key milling equipment after material has been crushed. It is widely used in cement, silicate, new construction material, refractory material, chemical fertilizer, ferrous metal and nonferrous metal as well as ceramics.

Cement Ball Mill authorSTREAM. The cement ball mill can perform dry process production and also wet process production moreover it can do grinding and drying at the same time. CHAENG cement ball mill has features of small investment high rate of return simple process and easy operation. Advantages of CHAENG cement ball mill: 1. Get Price

For a specific production rate in the pilot plant, an increase in the balls level from 25% to 30% leads to an increase in product fineness. But, adding balls from 30% to 35% does not mean that the final product will go finer than 78% passing on 75 μm as already achieved at 30% of ball filling degree.

Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry.

A disassembly of a cement ball mill with a weight of 500 tons. A manufacture of a cement mill with a weight of 450 tons. An installation of a ball mill with a weight of 450 tons, including an assembly of a modern ring gear.

internal structure of cement grinding mill grind mill structure,Raw Mill/Raw Mill Machine/Raw Ball Mill/Cement Raw Mill Largest suppliersShanghai MG is committed to provide users with the reliable and productive Raw Mill,Raw, Grinding mill iron ore use compact structure of model 5R4119, Grinding mill iron ore use compact structure .

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US [Newlybuilt] and about 230 million US [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US=¥110] Related matters

Dry ball mill is widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry. Working principle: Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and ...

It truly is improved to simplify the cement grinding approach, minimize the construction region and conserve the investment cost. Shanghai SBM is specialized in production significant sized cement grinding products together with cement mill, cement ball mill, cement .

ball mill cost for 100 ton cement production plant. High pressure roller press as pregrinding to ball mill the Industrial, ball mill cost for 100 ton cement production plant,In China this configuration is commonly installed in new plants using dry processes and during grinding system upgrades in existing plants, By installing a combined ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

Features of Superfine Ball Mill Production Line LHM: 1. Low energy consumption: our LHM superfine ball mill production line adopted high advanced energysaving technology and classification technique; as a result, our production line can save over 40% energy for producing same quantity materials.

Cement grinding Vertical roller mills versus ball mills RuCEM . cement industry the ball mill was really an epochmaking breakthrough as for ... applications of the vertical roller mill for cement .

Introduction of Chinaware Ball Mill/Ceramic Ball Mill. 1. Ceramic ball mill is widely used for material grinding in cement, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal, ceramics and other can be used for wet grinding and dry grinding.

cement machinery,cement making machinery,Tube Mill,Cement production line. ... The ends of the ball mill or end do not use the usual main bearing, but using slipper bearing. ... three or four, so its structure is not only fully applicable to small and medium sized mills, but without specification limit, you can also use the large mill. 2) using ...

There are two types of mills which are mostly used in cement plants for grinding raw mix viz. Ball mills and VRM. Ball mills Ball mills are essentially fine grinding units capable of grinding material to a fineness say 84% passing 90 microns. The size reduction technique involved here is attrition and impact. In ball mills, Hichrome steel balls are used to grind the raw material. The ball mill is located horizontally .

Ball mill is widely used in building materials, mineral processing, cement, thermal power generation and fertilizer production of the main grinding equipment, grinding ball is .