A sugar mill is a large factory used to produce raw sugar and other products from sugar cane. Mills are made up of a range of industrial plant such as boilers, storage and

sugar cane milling process

Sugar can be produced from sugarcane, sugarbeet or any other crop having sugar content. But in India, sugarcane is the main source of sugar. At present, this is the second largest agrobased industry of India after cotton textile industry. This industry involves a total capital investment of Rs. 1,250 crore and provides employment to lakh workers.

The fires burn off dead leaves and other biomass "trash" that would otherwise impede the harvest operation, increase transportation costs to the mill, interfere with milling machinery, and absorb sugar during the extraction process. Absorbed sugar cannot be .

Illovo's leading position in African sugar production is driven by our ongoing investment in the continent's growth story. As significant suppliers of sugar in our countries of operation and major exporters to regional markets, Illovo is strategically positioning its operations to respond to Africa's increasing sugar consumption growth, forecast to grow by six million tons by 2020.

Mar 01, 2017· Evaporated cane juice is produced by extracting the liquid from sugar cane, through the milling process. The "juice" is then filtered to remove any solids that may be present. At this point, the remaining liquid undergoes an evaporation process, producing a syrup.

Sugar Milling: Process Control Continuous control at each process step FTNIR allows for a fast and easy analysis of any sample in the sugar milling process regardless if it is a clear liquid, juice almost solid crystalized sample like massecuites the final raw sugar. All .

Cane Shredders prepares the cane before sugar extraction to increase crush rates at the line. This makes this equipment which makes it a vital part of the cane milling process. The shredding action of our Cane Shredders exposes more fiber particles and ruptures more sucrose bearing cells than knifing alone. This allows the mill or diffuser extraction process to maximize the removal of the sugar juice from the .

Sugar Production from Sugar Cane. The basic process. Sugar cane must be crushed to extract the juice. The crushing process must break up the hard nodes of the cane and flatten the stems. The juice is collected, filtered and sometimes treated and then boiled to drive off the excess water.

At the Sugar Mill. Rather than carting all that sugar cane around the world, the milling process starts right where it's grown. Sugar mills do the job of stripping away all the woody bits of the cane, and turning it into sticky syrup. It used to be that farmers would set fire to their cane fields just before harvesting.

The byproducts from cane sugar processing, namely the straw and bagasse (cane fibres), can be used to produce cellulosic ethanol, a secondgeneration biofuel. Other sugarcane products include molasses, rum, and cachaça (a Brazilian alcohol), and the plant itself can be used as thatch and as livestock fodder.

Major products. The sugarcane crop can produce up to million tonnes of raw sugar, 1 million tonnes of molasses and 10 million tonnes of bagasse (a fibrous cane residue) annually. Approximately 85% of the raw sugar produced in Queensland is exported, generating up to .

The sugar cane or other pulp from which juice is extracted, moves in the direction of the arrows, first between the feed and top roll 14 and 12, and then between the discharge and top rolls 16 and 12, and in the transition stage, the sugar cane or bagasse passes over a trash plate 18 spanning the space between the two lower mill rolls.

Queensland Sugar Limited operates a quality management scheme on behalf of the industry to ensure that raw sugar produced by mills meets customers' requirements. The quality and efficiency of the raw sugar production process have been assisted through improved milling technology and government and nongovernment research.

Sugar cane processing. Impurities are removed by clarification and then the juice is concentrated and crystallized. The crystal mass is sent to a centrifuge after which it is dried yielding golden raw sugar for transportation to refineries worldwide. The shredded cane residue, bagasse, is .

These efforts are beginning to pay off, with the first certified sugarcane offered from a Raízen mill in Sao Paulo, Brazil, and purchased by The CocaCola Company. WWF remains committed to transforming the sugar industry by calling on buyers of sugar to commit to Bonsucrocertified sugar as soon as possible.

A truck hauls cane to a sugar mill in Florida Sugarcane processing produces cane sugar (sucrose) from sugarcane. Other products of the processing include bagasse, molasses, and filtercake.

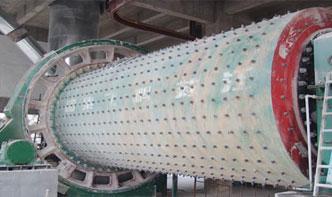

Custom manufacturer of sugar sugar cane mills for gentle milling, sieving, delumping for a range of applications in the food industry. Features include easier feed, cleaning, configuring under drive. Mill sieves are designed with a minimum of process parts can be disassembled for cleaning also allow rapid screen changing.

Several organizations have grown to meet the needs of people interested in making syrup or molasses from sugar cane or sorghum. Living history farms in the South sometimes have demonstrations of the pressing and boiling process. Check with groups like Syrupmakers for information on .

A world record for the sugar mill industry. Sugar set world milling record 2011/12 and announced a record harvest in 2012/13. The Clewiston facility's CTandem processed more than million tons of cane, setting a new world record for the extraction of sugar as the first single tandem in the world to grind over four million tons in a season.

Raw sugar manufacture. Sugarcane processing, outlined in Figure 2, is practiced in many variations, but the essential process consists of the following steps: extraction of the cane juice by milling or diffusion, clarification of the juice, concentration of the juice to syrup by evaporation, crystallization of sugar from the syrup, and separation and drying of the crystals.

Given the market prices of raw cane sugar and wholesale refined beet sugar in the United States, use of raw or refined sugar would be very costly to convert into ethanol. Ethanol production costs were estimated at per gallon using raw sugar as a feedstock and were estimated at per gallon using refined sugar. For these

Milling Plant Control ¾For each 1% of strange matter that enters to the sugar process, it's lost 1,5 Kg of sugar by ton. of processed cane ¾The preparation index defines the result of the preparing of the cane to be crushed. 90% is a good index ¾For each unit of difference between the purity of the mixed

The result of the milling process is pure whole unrefined noncentrifugal cane sugar, called Panela (right). The earliest modern record of Panela is around 3000BC in India, where Panela was known as Gur Jaggery, or more commonly today Gur, or 'poor people's sugar'.

Perry Videx is worldwide distributor of unused, used and reconditioned sugar processing machinery including entire sugar factories for sugar beet and/or sugar cane. Sugar processing equipment available includes: preparation machinery, feeders, heaters, purification/ bleaching machinery, evaporators, pan vacuum, crystallizer machinery, sugar condensers, pulp processing equipment, shredding machinery, .