The Correct Startup and Shutdown Method on Jaw Crusher Henan . jaw crusher which is widely used in various of industries has advantages of simple structure, reliable operation, easy maintenance and low production cost etc. Contact Supplier; The Correct Order to Start the Jaw Crusher and Its Using Method

method a jaw crusher

Jaw crushers operate according to the principle of pressure crushing. The crushing material is crushed in the wedgeshaped pit between the fixed crusher jaw and the crusher jaw articulated on an eccentric shaft. The material is crushed by the elliptic course of movement and transported downwards.

11 used for modelling cone crushers as well [8]. The BPM method is based on the principle of bonding particles together forming an agglomerated cluster. Despite the fact that the PBM approach is more computationally effective and easy to calibrate the BPM approach is chosen for this work.

jaw crusher maintenance method; or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that .

the feeding method and on feed characteristics such as gradation, bulk density, moisture, clay content and crushability. Measurement of the crusher's closed side setting varies depending on the jaw profile that is being used and has an impact on the crusher's capacity and product gradation. The following factors will enhance crusher

In order to analyze the force condition and crushing power of crusher teeth plate, the discrete element method models of jaw crusher and doublecavity jaw crusher are set up respectively using EDEM, a kind of software for discrete element analysis. Meanwhile, the working process, the loading force on the teeth plate and crushing power are simulated.

Sep 20, 2017· How can we reduce the risk of plugging a crusher in the first place and make unplugging a crusher safer? Preventing plugging improves productivity and improves safety and there are simple ways to do this. For example: the tipping hydraulic grizzly is one of the simplest ways there is to prevent plugging on a jaw plant.

the Jaw Crusher can be converted to suit different applications. The BB 51 is driven by a powerful singlephase AC motor with 1100 W. A disc spring package and thermal overload protection device protect the Jaw Crusher against overloading. Due to permanently lubricated bearings and its solid design, the BB 51 is virtually maintenancefree.

Jaw crushers range in terms of their size and operating capacity, but as a rule they fall somewhere in the middle of the full range of crusher sizes. In some cases they can be made portable, as is the case in some mining jaw crushers.

Methods of Measuring the Crushing Force of Jaw Crusher The crushing force of jaw crusher is the collection of material crushing resisting powers which have random variation in crushing cavity. These material crushing resisting powers that are constantly changing and have random distribution are crushing forces of the jaw crushing.

Crusher Size Reduction Ratio Calculation Method. Crusher size reduction ratio is the ratio of raw material particle size and particle size of crushing. Crusher size reduction ratio is the ratio of raw material particle size and particle size of method are the following:

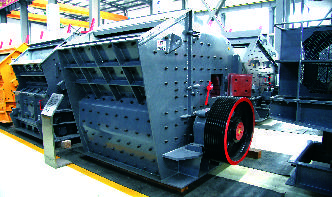

Powerscreen jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries. These machines are amongst the most advanced and reliable in the market and are highly productive in a variety of applications.

With the progress of the China national machinery industry, our country slowly in the use of performance improvements of jaw crusher, jaw crusher performance had greatly improved, here is how to optimize the main performance parameters of the jaw crusher and design, to ensure the crusher has the best performance in use, thus saving energy, increase production efficiency.

The Powerscreen Jaw crusher range starts with the Metrotrak which is a compact, high performance mobile jaw crushing plant featuring the "M" series single toggle jaw crusher. With an aggressive crushing action, the Powerscreen Metrotrak is capable of high throughput even at tight close side settings.

set. The method assumes that TBFs are independently and identically distributed (iid). To established validity of this assumption, statistical tests are performed to examine the presence of structure or trend in the data. Figure 1. Block diagram of operational units. Figure 2. A double toggle jaw crusher. Table 1. TBFs of the crusher and their components.

Dec 08, 2009· TYPES OF JAW CRUSHERS In the dodge jaw crusher the moving jaw is pivoted at the bottom. As minimum movement is at the bottom it has a greater tendency to choke. In the Blake or jaw crusher the moveable jaw is pivoted at top.

3. Wedge with two wedges placed between the backseat of the toggle plate and the frame. This method is suitable for small scale jaw crusher. Large jaw crusher can not be adjusted by human power, it generally uses hydraulic adjustment. Small jaw crusher generally uses wedge adjustment or support device adjustment.

JW Series Jaw Crusher Enquiry Details When enquiring about the range of ® JW Series Jaw Crushers please supply the following details so that the jaw crusher best suited may be recommended (email or fax this form to your local ® Minerals Processing Systems distributor).