Depending upon whether an ore deposit formed at the time of and together with the enclosing rock, or was introduced into it by subsequent processes, they are classed as: Syngenetic A deposit formed at the same time as the rocks in which it occurs. Ex. Banded Iron Formation

purifi ion process of iron ore

per ton of ingot steel. In iron ore concentration plants, water use is referred to both raw and concentrated ore. HOW WATER IS USED Most of the water used in the iron and steel industry is used for cooling, to protect equipment and to improve the working conditions

passes it through a filter paper, and runs an iron test on the clean, filtered water (filtrate). If no iron is present, it has all been oxidized and is being removed in the filtration process. If iron is found in the filtrate, oxidation has not been complete and some of the iron will pass through the filter and end up in the treated water.

Iron ore treatment process Nov 13, 2017· The process of sintering is basically a pretreatment process step during iron making to produce charge material called sinter for the blast furnace from iron ore fines and also from metallurgical wastes (collected dusts, sludge and .

Iron Problems in Well Water After hardness in well water, iron is the most common water problem dealt with by homeowners with well, iron is also difficult to treat to a satisfactory level. This difficulty is due to the fact that iron can be found in well water in several forms, each of which may require a different water treatment for removal or control.

The bauxite is purified by the Bayer Process. First the ore is mixed with a hot concentrated solution of sodium hydroxide. The NaOH will dissolve the oxides of aluminum and silicon but not other impurities such as iron oxides, which remains insoluble. The insoluble materials are removed by filtration.

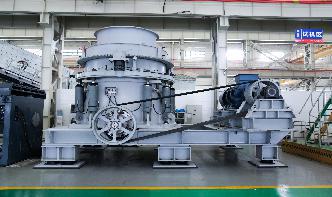

extraction and purification of iron from its ore is a leading global manufacturer of crushing and milling equipment (extraction and purification of iron from its ore), also supply individual (extraction and purification of iron from its ore...) crushers and mills as well as spare parts of them.

Jan 15, 2019· This study proposes a novel process for the separation of particulate matter (PM) from the flue gas emitted from ironore sintering operations using a magnetically stabilized fluidized bed (MSFB) with sintered ore as a filter medium. The deactivated sintered ore can still be used as a raw material for subsequent sintering operations.

May 22, 2009· The Step by Step Process of Extracting Iron from its Ore using the Blast Furnace with details of Chemical Reactions. Question Answers based on the process of extraction of metals.

Iron ore is abundant, but its isolation is an energyintensive process. The chief ores are the oxides hematite, Fe 2 O 3, and magnetite, Fe 3 O 4, and its carbonate siderite, FeCO 3 . Iron also forms the oxide minerals lepidocrocite and goethite, each with the general formula FeO(OH).

Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process. Also during the processing of high grade iron ores which don't need beneficiated, fines which are generated can be pelletized and used instead of being disposed of.

The process of removing phosphorus from iron ore linked to the concept of selective agglomeration is well grounded in the work of Sirianni et al.. Sparks and Sirianni (1974) applied the technique to remove the iron ore's phosphorus from Snake River, northern Canada. The content of phosphorus was in the range of % unacceptable for steel ...

commercially pure iron, subsequently leading to discussion of the ironcarbon alloy system that is the basis for all steels and their heat treatment. All pure metals, as well as alloys, have individual constitutional or phase diagrams. As a rule, percentages of two principal elements are

Aug 29, 2017· I am not at all sure what it is that you are after. Could it be that you are asking about three principal septs in the mining, smelting and purification to produce iron ingots suitable for use in manufacturing? That would be MINING, SMELTING AND R...

Höganäs spongeiron process and the wateratomizing process. The former process is based on reduction of iron ore, yielding a highly porous spongeiron which subsequently is comminuted to powder. The latter process is based on atomization of a stream of liquid iron (or steel) by means of a jet of pressurized water. Both processes will be ...