Part C is then added and incorporated in the mixture of parts A and B by any of the methods indicated for preparation of the pigment slurry in Examples I. II, and V, that is by pony mixer, colloid mill, pebble or ball mill. or roller mill if the watercontent is sumciently reduced.

the use of ball mill in preparation of emulsion

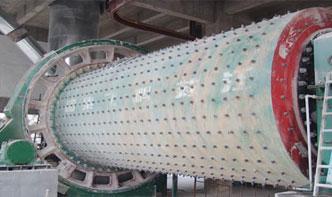

Sep 28, 2014· BALL MILL It is used for size reduction fine solid discrete particles or for deagglomeration of very tightly bound agglomerates. The machine consists of cylindrical drum into which a charge of heavy spherical balls usually metal or ceramic is loaded along with the components of the dispersion.

Jun 30, 2002· Emulsion polymers are widely used as the polymeric base for a variety . . . In 2000, demand for emulsion polymers in the global adhesives industry totaled million metric tons (dry basis), valued at billion.

They perform best in holes larger than 152 mm in diameter. INNOVEX™ 204 and INNOVEX™ 205 are transported and stored as bulk product. They are blended and sensitised in our explosives trucks onsite during application. BME is able to formulate any ratio of emulsion to prill to provide the energy and VOD to match your rock and blasting requirement.

Emulsion Preparation Waterinoil (W/O) emulsions were prepared by homogenization using a high speed homogenizer (UltraturraxT25, IKA, Germany) at 24000 rpm for 10 min. Continuous phases were prepared by dissolving a certain amount of PGPR (1, 3 and 5% (w/w)) in an oil phase (the sunflower oil, the pumpkin seed oil and a mixture of the oils (mass ratio 1:1)) at 50 °C, by mixing on a magnetic stirrer for 30 .

Nov 12, 2012· Prepare and use the right consistency emulsion paint for the surface in question On new plaster, the conventional approach is to apply a wash coat plus 2 top coats. Or on existing painted walls, after various degrees of filling and sanding and priming, apply 2 top coats.

A bitumen emulsion is a dispersion of bitumen in water. However, in the same way as water and oil do not mix easily, water and bitumen together do not get on. At RAD International, Bitumen emulsions are made using ATOMIX ® colloid mill, In the colloid mill energy is applied to the system by passing the mixture of hot bitumen and water phase ...

More Information Top. Descrip.: Acrylic emulsion; an ionic emulsifying system Category / Applications : Thermoplastic emulsion designed for maintenance paints for metal due to excellent corro sion resistance, outdoor durability, good stability to reactive pigments, excellent adhesion, ease of .

mill for pigment emulsion manufacturer, steel ball mills,sigma kneader,steel ball mill ..... batch ball and rod mills and batch drive roll net weight 45 lbs rpm 47 79, ... 40 CFR Part 438 eCFR — Code of Federal Regulations Abrasive blasting includes bead, grit, shot, and sand blasting, and may be performed ...

Purpose The article reports a wet milling process, where the planetary ball mill was combined with pearl milling technology to reach nanosize range of meloxicam (Mel; 100–500 nm).

Bitumen Emulsion Plant Colloid Mill For Bitumen Emulsion Manufacturer of Bitumen Emulsion Plant Colloid Mill For Bitumen Emulsion, Asphalt Emulsion Plant, Turnkey Bitumen Emulsion Plant and Continuous Bitumen Emulsion Plant offered by Wahal Engineers, New Delhi, Delhi.

Since many years, nanosuspensions are prepared through wet grinding processes by using pearl ball mill. Nowadays, nanosuspensions can be prepared by dry milling methods. Stable nanosuspensions are prepared by using dry grinding of poorly soluble drug with soluble polymers and copolymers after dispersing in liquid medium.

The first step in making paint involves mixing the pigment with resin, solvents, and additives to form a paste. If the paint is to be for industrial use, it usually is then routed into a sand mill, a large cylinder that agitates tiny particles of sand or silica to grind the pigment particles, making them smaller and dispersing them throughout the mixture.

Rotary mills and ball mills are also crushers for fine fragmentation of dry material. Dry grinding allows to use large fragments of source material, since the impact of the balls is more efficient than the "wet" grinding. At the same time, the "wet" grinding mills are the .

Background. Paint is a term used to describe a number of substances that consist of a pigment suspended in a liquid or paste vehicle such as oil or water. With a brush, a roller, or a spray gun, paint is applied in a thin coat to various surfaces such as wood, metal, or stone.

The temperature was main Table 5. Different batches of emulsion paint were tained at 80°C, and the polymerization was carried out formulated using various amount of core–shell latex for another 3 h. Then it was cooled to room temper along with TiO2 as pigment in a standard ball mill.

Ball mills A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Bead Mills Raymer Engineering Most Trusted Manufacturer, Supplier and Exporters of Bead Mill in MumbaiIndia. The actual dispersion system in a bead mill consists of a milling chamber and an agitator; the milling chamber is filled with the grinding beads (material glass, zircon oxide, steel) and the product to be dispersed.

Mar 23, 2017· A microfluidic device was also employed by Liu and others to prepare alginate core–shell microparticles (size 220 to 320 μm) using a similar O/W/O emulsion preparation procedure, but in this case the alginate gelation was triggered by Ca 2+ ions released from CaCO 3 nanoparticles after exposure of a photo‐acid generator to ultraviolet light.

Find Grinding Emulsion related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Grinding Emulsion information. ... The Vibratory Micro Mill PULVERISETTE 0 is recommended for sample preparation of RoHS tests (Restriction of Hazardous Substances). Method of operation The Equipment Types: Ball / Media Mill ...

Bematek colloid mills are recognized as the equipment of choice for increasing the stability of suspensions or emulsions in today's complex homogenizing processes. The Bematek CZ Sanitary and CK Industrial series colloid mills provide manufacturers with simple, repeatable processing capabilities, for fineemulsion stability and dispersion ...

Jan 31, 2017· The development and processing of emulsions is common in many industries. A manufacturer that uses a tooling lubricant to produce aircraft engine parts or someone applying a cosmetic cream are common examples of emulsion use. The use of colloid mills and inline mixers is a popular way to prepare and process emulsions.