Cement and global warming • Making cement results in high levels of CO 2 output. • Cement production is the third ranking producer of anthropogenic (manmade) CO 2 in the world after transport and energy generation. • 4 5% of the worldwide total of CO 2 emissions is caused by cement production. • CO 2 is produced at two points during cement production :

cement clinker techniques

Clinker : Gypsum : Typical Close Circuit Finish Grinding With High Efficiency Separator : Cement Cooler Cement Silo : High Efficiency Separator ∑Control particle size distribution : Water spray : Gypsum dosing : Control hydration reaction Obtain optimal dosing : Additives : Additives dosing : Reduce strength deviation Regulate strength : Mill temperature control

Clinker and cement production is mainly controlled by Xray fluorescence analysis (XRF), where phase abundance is calculated from the chemical composition using the Bogue method. Unfortunately the absolute amounts of phase content cannot be determined.

Methods for suppressing cement clinker dust emissions. The is provided with an effective deing agent which, upon slurrying of the clinker and other ingredients (, sand, gypsum, aggregate) to form the desired mortar, inhibits formation in the mortar, thus not significantly increasing air entrapped in the slurried mortar.

Mar 20, 2019· A new Standard Reference Material (SRM) for portland cement clinker has been produced for the Office of Standard Reference Materials at the National Institute of Standards and Technology (NIST). The SRM clinkers are intended for use in developing and testing quantitative methods of .

Chapter 3. Cement and concrete characterization. They are also important as a basic input for modelling the microstructure, and as a check as to how well that microstructure has been modelled. Xray diffraction, especially as interpreted by Rietveld analysis, can give very precise information on phase composition of cements and clinkers.

In both spectra, SRM Cement Clinker 2686a is red, and SRM Portland Clinker 2688 is the yellow overlay. The Portland Clinker has iron oxide at %, while the Cement Clinker has iron oxide at %. The small variation in concentration is easily seen in the overlay. XRF is .

Xray fluorescence (XRF), a standard technique across the cement industry, is used to determine metaloxide concentrations and oxide stoichiometry. Xray diffraction (XRD) provides quantitative analysis of free lime in clinker, which is critical to the production process.

The clinker burning process is the most important part of the process in terms of the key environmental issues for cement manufacture: energy use and emissions to air. Figure 1. Process flow diagram for the manufacture of cement [6]. To produce 1 tone of clinker, the typical average consumption of raw materials in the EU is tones.

CEMBUREAU is the European Cement Association. Our primary audience is Europe both policymakers and their relevant stakeholders. In this regard, we communicate the industry's views on all technical, environmental, energy and downstream issues and policy developments.

Cement production using dry process involves three fundamental stages which are: preparation of the raw materials, production of the clinker and preparation of the cement. The first step in the production of cement is usually the preparation of the raw materials.

The gypsum controls the rate of hydration of the cement in the cementsetting process. Significant amounts of electric power are required to operate the clinker mills depending on the fineness of the prod uct and the distribution of particle size. The finer the grind, the more reactive is the finished cement.

AIR POLLUTION CONTROL TECHNIQUES FOR THE CEMENT MANUFACTURING INDUSTRY: A CASE STUDY FOR ZIMBABWE D. Zimwara1, L. Mugwagwa1, ... oxide at high temperatures to form clinker; the clinker is then ground or milled together ... Carbon dioxide is released during the production of clinker, a component of cement, in which calcium carbonate (CaCO ...

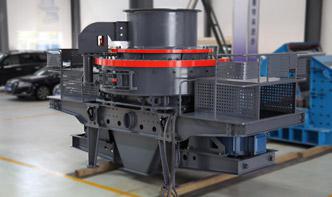

Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products. The lumps or nodules of clinker are usually of diameter 3.

Portland cement, the most common type of cement, is made by mining, and then grinding raw materials that include limestone, clay, and bauxite to a fine powder, called raw meal. This is then heated in a rotating cement kiln. This process produces clinker: rounded nodules between 1mm and 25mm across.

for cement manufacturing can be wet or 2dry. Cement production using dry process involves three fundamental stages which are: preparation of the raw materials, production of the clinker and preparation of the cement. The first step in the production of cement is usually the preparation of the raw materials.

AIR POLLUTION CONTROL IN THE CEMENT INDUSTRY. by Russell E. Hailstone Technical Director General Portland Cement Company ... Burning changes raw mix chemically into cement clinker (V6) 236: Clinker with gypsum added is ground into Portland cement and shipped: 237 ... on "Control Techniques for Particulate Air Pollutants", ...

The benefits of using this substance are clear. First of all, its altered chemical composition and its manufacturing at a temperature that is 150 to 200° C lower result in CO 2 emissions that are up to 30% lower than those generated by the production of normal Portland cement clinker. Energy efficiency is also improved, as the lower burning temperature reduces fuel consumption by roughly 10%.

Portland cement clinker was first made (in 1825) in a modified form of the traditional static lime kiln. The basic, eggcup shaped lime kiln was provided with a conical or beehive shaped extension to increase draught and thus obtain the higher temperature needed to make cement clinker. For nearly half a century, this design, and minor modifications, remained the only method of manufacture.

Jaber Malandi, Bedeschi (Italy) Cement and clinker export terminals: case studies from Turkey, Tunisia and Greece. Juliano Arantes and Osman Nemli, ABB (Switzerland) Bursa Çimento improves energy and process efficiency with ABB's Expert Optimizer.

« Clinker (Lapstrake) Construction Techniques » Is it up to the builder to decide the placement of the planks in clinker boatbuilding? The plans do not give the positions of the individual planks. Lining out is the job of the builder and can only really be done in three dimensions. In clinker construction where the plank lines show, it is ...

storage piles. The material handling equipment used to transport clinker from the clinker coolers to storage and then to the finish mill is similar to that used to transport raw materials ( belt conveyors, deep bucket conveyors, and bucket elevators). To produce powdered cement, the nodules of clinker are ground to the consistency of powder.