May 22, 2009· The Step by Step Process of Extracting Iron from its Ore using the Blast Furnace with details of Chemical Reactions. ... People discovered that a high temperature coal fire could be used for the extraction of iron from iron ore. The discovery of electricity at the beginning of the nineteenth century allowed the extraction of the more reactive ...

the major steps in the process of iron ore mining feb

steps to process iron ore . the major steps in the process of iron ore mining. Iron ore is a type of mineral and rock from which metallic iron is extracted economically. This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty red.

Jan 10, 2013· major steps in the process of separation from ore from other rock .. diy rock crusher for gold ore – Gold Ore Crusher .rock gold mining: The gold is found within a rock ore, such as a quartz vein, and the gold bearing vein is . »More detailed

PDF | Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents and solid fuel (coke). The purpose of ...

Ironore Mining in Carajás Ore mining began in Carajás in 1967 in what was expected to be a project that would exploit the world's largest highgrade iron ore by Vale, .

Jan 15, 2012· Gypsum production process. If the moisture content of the mined ore is greater than about weight percent, the ore must be dried in a rotary dryer or a heated roller mill. Ore dried in a rotary dryer is conveyed to a roller mill, where it is ground to the extent that 90 percent of it is less 149 micrometers (µm) (100 mesh).

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,

Extraction Process of Aluminium from Bauxite Ore. The separation of the alumina from the impurities in the bauxite ore is usually accomplished by the Bayer Process. In this process the ground bauxite is leached with caustic soda (NaOH) to produce soluble sodium aluminate (NaAlO2), leaving the impurities in the insoluble residue.

How Is Iron Extracted From the Earth? Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining. The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace ...

Jan 18, 2017· The Amalgamation Process that employed mercury in the recovery of gold from the ore is no longer used at most major mines, but goldrich ore often has some traces of mercury that may still stick to gold even after the precipitation and the leaching process. If not removed from the ore this mercury is likely to under volatilization during the smelting process and can cause serious health and .

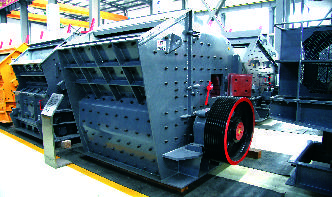

Applications Crusher FAQ . The slurry then flows to the next step in the process called flotation. Copper ore concentration plants, copper processing equipment . Each process consists of several steps in which unwanted materials are . This process is called concentrating and is usually done by the flotation method. Smelting.

then reacts with the iron ore to form carbon dioxide and pure iron. Separating the iron from the slag 2 The melted iron sinks to the bottom of the furnace. The limestone combines with the rock and other impurities in the ore to form a slag which is lighter than the iron and floats on top.

The next step in development was the construction of a forge on Carp River, about three miles from the Jackson Mine, and on February 10, 1848, the first iron from the Lake Superior region was made in this forge by Ariel N. Berney.

Tula region also known as Kursk Magnetic Anomaly is having large reserve of iron ore. This region produces highgrade iron ore. Orel and Veroneth are two major areas of this region. (iii) NorthWest Russia: In this region Murmansk and Kovador are significant mining areas of iron ore.

Mar 20, 2016· It depends on the type of mining to some extent, but quite often it follows 5 general steps. The type of mining depends on the geological and topographic setting that mineral deposits are found in. But generally speaking there are about 5 steps to most mining operations, as follows: 1) exploration and development mineral deposits of suitable size and geological setting are worked up and the ...

Cast iron has already been mentioned above. This section deals with the types of iron and steel which are produced as a result of the steelmaking process. Wrought iron: If all the carbon is removed from the iron to give high purity iron, it is known as wrought iron. Wrought iron is quite soft and easily worked and has little structural strength.