The present invention refers to a system and method for the totally dry treatment of ironore wastes from previous mining operations, suitable for both the processing of ore wastes deposited in barrages and wastes stored in piles.

iron ore fines processing plant

The processing capacity of the plant in this instance is 200 t/h of 40 mm material and the washed products are 5 mm washed fines in addition to 5–16 mm and +16 mm washed ore. The washed ore is subsequently used as input to the blast furnace.

Our heavyduty iron ore balling drums are relied on by some of the industry's top producers to process iron ore fines into pellets for the steelmaking process. The use of a disc pelletizer is a popular alternative approach to pelletizing iron ore fines, as this offers more control over pellet size and produces a more refined pellet product. Additionally, this approach offers significantly less recycle than a balling drum .

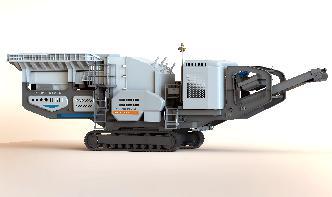

Iron Ore Processing Plant is mainly composed of jaw crusher, ball mill, spiral classifier, mixer, magnetic separator, ore concentrator and dryer machine, and combined with ore feeder, bucket elevator and belt conveyor. a complete ore beneficiation production line can be formed.

Processing plant. The processing plant consists of six individual scrubbing, screening and desanding circuits. The wet scrubbing units are used to break down the sticky clays attached to the ore, into a fine suspended clay fraction suitable for subsequent wet beneficiation. Beneficiation is the process of separating the valuable material from the

Influence of beneficiation plant pellet grade iron ore fines size on ... JSW Steel Limited is a Mtpa integrated steel plant and 2 corex 4 blast furnace forms the main iron making ... Sinter and pellet are the main iron bearing feed to iron making units. ... iron ore .

Mine processing. Roy Hill's purpose built, world class mine processing plant utilises low risk, proven technology to process 55Mtpa (Wet) of lump and fines iron ore and is the largest single feed processing plant in the Pilbara region. A wet processing and beneficiating model has been selected, as approximately 70 per cent

offers 1,821 iron ore processing plant products. About 30% of these are mineral separator, 19% are crusher, and 9% are mine mill. A wide variety of iron ore processing plant options are available to you, such as free samples.

Iron ore is used in production of pig iron which is further used in production of steel other uses of iron ore are like industrial finishes, polishing compounds and sponge iron industries.

May 31, 2018· Iron ore beneficiation is the process of purifying raw iron ore before smelting it If this process isn't completed Beneficiation of an iron ore fines by magnetization Nov 10, 2017 · For this purpose, the beneficiation of a lowgrade hematite ore fines containing carbonate minerals with magnetization roasting and magnetic separation was proposed for the first time.

PDF | Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents and solid fuel (coke). The purpose of ...

The Silver Yards Processing Facility is located 1 km from the James mine and forms part of LIM's Stage 1 DSO operations with the objective to beneficiate ore from the Central Zone deposits. The facility comprises the dry and wet process plants, as well as a 6 km railway spur that connects to the main rail line transporting iron ore down to the Port of SeptIles.

Iron ore processing plants. These plants will help to increase the quality of the raw materials and to refine the goods. Today the raw materials extracted from the mines are transported to the processing plants and then processed in several steps directly to fines and lumps with their respectively high iron contents.

There are 1,798 iron ore processing plant suppliers, mainly located in Asia. The top supplying country is China (Mainland), which supply of iron ore processing plant respectively. Iron ore processing plant products are most popular in Africa, Southeast Asia, and Domestic Market.

then reacts with the iron ore to form carbon dioxide and pure iron. Separating the iron from the slag 2 The melted iron sinks to the bottom of the furnace. Get Price

South Flank will be the largest iron ore processing facility ever built in Western Australia. The project will include an 80milliontonperyear crushing and screening .