Aug 30, 2012· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

raw gypsum for cement

The heating that occurs in the kiln transforms the raw materials into new chemical compounds. Therefore, the chemical composition of the cement is defined by the mass percentages and composition of the raw sources of lime, iron, silica, and alumina as well as the temperature and duration of heating.

Raw gypsum is being exported in big quantities particularly to India. ... Cement industry worried as raw material evaporating fast . ... Published in The Express Tribune, ...

Clinker is then finally pulverized by grinding into a very fine powder and is finally mixed with calcium sulfatae or gypsum to obtain cement. Raw Materials of Portland Cement. The commonly raw material included in cement is as follow. (a) Calcareous materials and (b) argillaceous materials.

Sep 22, 2011· Calcining and Second Grind Raw gypsum rock is crushed before it arrives at the wallboard plant. Once there, it is heated to 350 F in a process called calcining, which removes 75 percent of the molecularly bonded water.

Sep 22, 2016· (2) The Mixing Amount of Gypsum. Gypsum is called the retarding agent of cement which is mainly used for regulating the setting time of cement and is an indispensable component. Without gypsum, cement clinker can condense immediately by mixing with water and release heat.

Fiber cement board offered by sinoceiling as new material is free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance, widely used as interior and exterior wall, suspended ceiling decoration.

of cement production and dispose of phosphogypsum as chemical and radioactive waste. Fresh wet hemihydrate phosphogypsum, cement and pozzolana additive were mechanically activated PG, these mixes were prepared at different replacements (by weight) of raw gypsum .

The rising costs of raw materials like gypsum has played a heavy strain on the cement and construction industry. As result, many asian cement and plaster board companies have to explore alternate sources for gypsum. Cement producers in Asia are dependent on the import of high quality natural gypsum, mainly from Thailand.

construction procedures for gypsum drywall, cement board, veneer plaster and conventional plaster construction in effect in 2004. Information, standards, products, product names, properties, applica ... use recycled and sustainable raw materials in product formulation and development. Using recycled goods as raw material provides numer

Gypsum is a raw material used mainly in the production of plasterboard and is also a key ingredient for producing cement. Due to having fireresistant qualities, it has been the material of choice for building structures since ancient times.

Specification C 22/C 22M, Specification for Gypsum, is the standard for the raw gypsum used to manufacture gypsum board or gypsum plaster. It provides the benchmark for evaluating gypsum ore, synthetic gypsum, or gypsum from any other source (including recycled gypsum board) for use by the gypsum board or plaster manufacturer.

HYDROCAL White Gypsum Cement A neutral gypsum cement having a normal set of 25 minutes. When formed under a template it is slightly on "short side" and has a tendency to tear. The setting expansion is somewhat greater than with A11 or B11 cements, but higher wet and dry strength is provided.

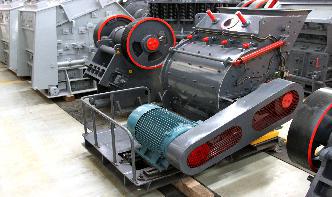

The rising costs of raw materials like gypsum (Fig. 1) and coal have been playing a heavy strain on the cement and construction industry. As result, Indian cement and plaster board companies have to explore alternate sources of gypsum and coal.

During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding process. Gypsum is added to control the "setting of cement". If not added, the cement will set immediately after mixing of water leaving no time for concrete placing.

MATERIAL AND ENERGY BALANCE OF PRODUCTION OF ... one of the oldest connective material, in addition to cement and lime is one of the most used binding material. Gypsum has many shortcomings, but also a lot of precious features, which can be ... that is used for thermal treatment of raw gypsum (r otational furnace, steamer, mill – driers, etc).

South Africa: A ship carrying clinker and gypsum has arrived at the Port of Ngqura. The raw material is intended for Osho Cement, a company setting up a grinding plant at Coega special economic zone, according to the Herald newspaper. The imported clinker and gypsum was transported by .

Apr 17, 2017· Due to limited local supply, the Indian cement industry is dependent on the import of 123 million t of gypsum. Existing major Thai gypsum consumers are expected to import over 118 million tpy of gypsum. The UAE, Qatar, Kuwait, and Bahrain are estimated to import over 26 million tpy of gypsum.

Gypsum is a mineral and is hydrated calcium sulphate in chemical form. Gypsum plays a very important role in controlling the rate of hardening of the cement, so its is generally termed as retarding agent of cement. It is mainly used for regulating the setting time of cement and is an indispensable ...