Kampala Cement Co Ltd is a new Cement Manufacturer in Uganda. The plant has installed capacity of one million tons of cement under brand names of Nyati .

manual raw mill dari cementplants

efficient raw mill feeding," said George Pischinas, Technical Consultant at the plant. "I would recommend it highly for level measurement on raw material silos for mills!" At the time, ultrasonics was a perfectly adequate solution, but dusty environments, even moderate ones like the ones at Heracles, reduce the

BHM3 simple dry mortar production line (also called by simple dry mortar plant, small putty production line) is on the basis of efficient ribbon powder mixer, with adding configuration of hoist feeder, material storage tank, automatic filling machine and electric control cabinet, to form a effective and reasonable, easy operation production line.

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system.

Cement Analysis and Production Information. ... These additives, along with the limestone, are fed from bins to the raw mill. An extremely important step in the cement process is to proportionally feed these materials to the raw mill to ensure the correct "blend" of these materials. ... Coal is still used in approximately 90% of cement ...

Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries. Plant engineering solutions for any mission | Loesche

Cement Mill, Raw Mill, Coal Mill, cement stone mechinary, We can provide you the complete stone cement data book duda pdf Shanghai SCM Company. This is chemist / safwan elfar website, highlighting cement industry in general Cement Manufacturing Process ((2)Cement Data Book, Duda, 2nd edition). hull for a cement plant in the Philippines

of understanding the raw materials' characterisation. Planning in this way will not only reduce the likelihood of downtime, but also reduce the need for manual intervention. Many cement plants are faced with having to manually clear blockages, which is a highly labourintensive way of managing the problem. Reducing the need for people

Raw meal shall get into the preheating decomposition system after homogenization where decomposition rate is about 95%, and raw meal is calcined into clinker in the rotary kiln, the formation of clinker. Then Clinker, gypsum and mixture is ground into qualified fineness cement in the cement mill.

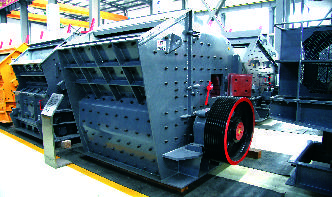

ZENTIH with full name: ZENITH coming from China is a professional manufacturer of stone crusher, grinding mill, optional equipments, and related mining equipments for sale in mining industry. Jaw crusher is the widely used primary stationary crusher and crawler type mobile crusher is the new model crushing equipment in recent years.

Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue. Woven fabric is a textile formed by weaving. It is produced on a loom, and made of many threads woven on a warp and a weft. Woven polypropylene/HDPE bags

Design of Large Size Cement Plants. Gearboxes Classification. TE B Gearbox design Oral Questions. Cement Plant. Schneckenpumpe Eng 10 2007Ibau Pump Manual. ... RAW MILL VERTICAL ROLLER Shaft Alignment. ILC Kiln Manual Ed1. 11IKN 016 0000 Pendulum Leaflet R1 .

Cement Analysis and Production Information. ... These additives, along with the limestone, are fed from bins to the raw mill. An extremely important step in the cement process is to proportionally feed these materials to the raw mill to ensure the correct "blend" of these materials. ... Coal is still used in approximately 90% of cement ...

EPA Instructional Manual for Clarification of Startup in Source Categories Affected by New Source ... First introduction of raw material with potential for emis'sion of pollutant(s) .5. Mechanical acceptance of plant ... Portland cement plants 4. Nitric acid plants 5. Sulfuric acid plants 6. Asphalt concrete plants 7. Petroleum ...

Engineering co., Ltd. is an engineering workshop established in 2003. Our services, mainly, reconditioning, reengineering, fabricating, manufacturing, measuring, testing and installation of all processes for all industries specialize in metallurgy with support from our design team on CAD/CAM design and raw material analysis service.

sulfur found in the raw materials used by cement plants. The SO 3 could react with calcium 3 "Industrial" boilers as a term used in the Control Cost Manual is meant to cover not only industrial but also commercial and institutional (or ICI) boilers, unless noted otherwise.

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw .

Energy Efficiency Improvement Opportunities Table 1. Energy Efficiency Measures and Technologies for the Cement Industry. Raw Materials Preparation All Kilns Efficient transport systems (dry process) Improved refractories Raw meal blending systems (dry process) Kiln shell heat loss reduction Process control vertical mill (dry process)

take care of (eg kilns or mills). The best possible control strategy is implemented and continuously applied on a computer linked with the instrumentation and control system. The system monitors and controls the kiln, cooler and for the vertical roller mills of raw mill, cement mill and coal mill process to optimise the cement production.

The largest single source of PM10 within cement plants is the pyroprocessing system that includes the kiln and raw material grinding exhaust stacks. Additional sources of PM10 are raw material storage piles, conveyors, storage silos, and unloading facilities. The major constituents of PM10 as cement kiln dust are alumina, silica, calcium ...