2. Weigh the charcoal. To every 100 grams of charcoal, add 67 grams of sulfur, and fill 1/4th of your ball mill with this mixture. Put the media in and let the mill run for 8 hours. 3. While the mill is running, place 600 ml isopropylalcohol in a large container for every 100 grams of charcoal/sulfur mix you have, and place it in the fridge. 4.

mill ball to powder ratio

The ball mill system consists of one turn disc (turn table) and two or four bowls. The turn disc rotates in one direction while the bowls rotate in the opposite direction. The centrifugal forces, created by the rotation of the bowl around its own axis together with the rotation of the turn disc, are applied to the powder mixture and milling balls in the bowl.

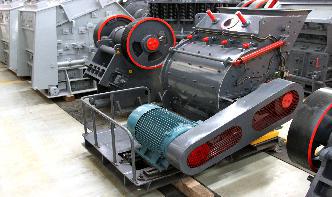

Ball Mill Design Manufacturing Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's.

Weight Ratio (All other weights depends on how much active powder you will use): ... Grind mill the active and conductive power for about 30 minutes. *Grind milling via MTI MSKSFM series Ball miller is suggested, please click the underline to view product details.* 4. Make liquid thickening agent: heat up deionized water to 80C and then ...

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

Laboratory Powder Milling Machine. Planetary ball mill is a necessary device for mixing, fine grinding, sample preparation, dispersion of nano material, new product development and small batch production of high technology materials. It is small in size, full in function, high in efficiency.

Metal Powder Discrete particles of elemental metals or alloys normally within the size range of to 1000 microns. Milling The mechanical treatment of metal powder, or metal powder mixtures, as in a ball mill, to alter the size or shape of the individual particles, .

Aug 11, 2007· Have an open when searching for this. It is definitely the most expensive and most important part in your ball mill, but if you look around enough you can surely find one for free. The motor should probably run at a least 500 rpm. Higher is fine; it'll just mean you'll need a greater reduction ratio.

How to Substitute Milk for Milk Powder 1 Replace all of the added liquids in the recipe with the same amount of liquid milk, up to 1 1/2 cups. The amount of milk added to breads is especially important, as using more than 1/2 cup of dry milk or its equivalent of 1 1/2 cups of liquid milk could result in a decrease in the volume of the bread loaf.

Ball mills can be used to further break down or refine a single material, or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial solution for mixing glazes that require the smallest of mesh sizes.

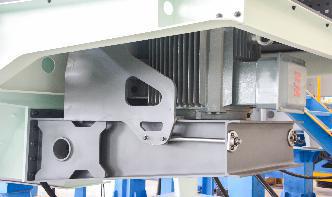

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product. The size of a mill is usually characterized by the ratio "length to diameter" and this ratio most frequently varies from to

Jan 30, 2017· Powder Coating Issues Related To Powder Particle Size. Powder coating particle size discrepancies can create issues with the quality of your finish and can increase your applied cost. These problems can be especially troublesome in a production environment, especially if you use a reclaim system as opposed to spraytowaste.

Design Method of Ball Mill by Discrete Element Method collected. The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation). Details of the experimental conditions are given in Table 2. Results and Discussion 1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis

The length to diameter ratio of cylindrical mills range from 1 to 1 through 3 to 1. When the L/D ratio is 2 to 1 or greater, we refer to the mill as a Tube Mill. Trunnion overflow discharge A trunnion overflow mill has an open discharge end. Material flows through the trunnion as a result of the pulp gradient between the feed and discharge openings.

Black Powder Basics. While there are different grades of black powder, it's made using the same three basic chemicals: potassium nitrate, charcoal, sulfur in a 6:1:1 or 6:: ratio or about 75% potassium nitrate, 15% charcoal, and 10% sulfur.

Vibratory ball mills Preparation of very Poor yield 22 fine powder Tumbler ball mills Large scale production of Consumption and wastage of 23,32 commercial alloys huge energy: only 20% of the consumed energy is utilized in comminution and the rest is wasted Planetary ball mills Laboratory based Insignificant for large 25,31

Besides, the raw mill has two forms of milling, one is an open form, and the other is a recycle close form equipped with powder concentrator. It is widely applied to many industries and has convenient operation. Features 1. Strong adaptability to raw material 2. Continuous production 3. Large crushing ratio 4. Easy to adjust the size of the products 5.